Royal Live Centers

Royal Live Centers are widely regarded by top metalworking professionals as the best live centers available anywhere in the world.

Each Royal center is a finely crafted tool, incorporating the highest quality steels, bearings, lubricants, and seals for unparalleled accuracy, rigidity, and durability.

Royal High Performance Live Center Features and Benefits:

- Guaranteed accurate to ± 0.00005” TIR or better.

- Exclusive Royal Roto-Shield™ coolant slinger extends bearing life by up to 300%.

- Optimized point geometries for maximum rigidity.

- Wide range of in-stock standard models to suit most common turning applications.

- Immediate delivery of “Off-The-Shelf” special centers

The exclusive Royal Roto-Shield™ represents a breakthrough in live center technology, significantly increasing effective operating life and overall value. Royal Roto-Shield™ Technology consists of two main components:

- A live center point machined from an oversized solid bar to incorporate a specially shaped integral coolant slinger.

- A long-life, spring-loaded seal that is resistant to abrasion, high temperatures, and virtually all metalworking fluids.

A dramatic increase in operating life is achieved through the following effects:

- Coolant is deflected, preventing it from penetrating the center and flushing out the grease.

- Bearings are protected from harmful fines and dust.

- Seal wear is minimized.

- Lubricating grease maintains consistency and lubricity.

Insist on Royal Roto-Shield™ Technology – Only Available on Royal Live Centers

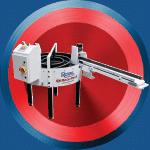

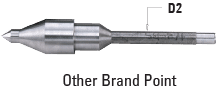

Some manufacturers believe that a long, thin point provides more rigidity than a short, thick point. But in fact, the opposite is true.

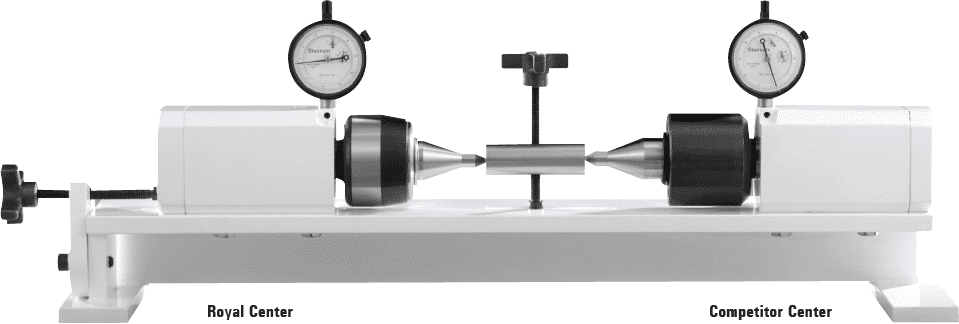

In order to verify that Royal’s short, thick point provides superior rigidity over a long, thin point, we built the test fixture pictured above.

Here’s how it works:

- Both live centers have holes drilled in their shanks corresponding to the indicator locations.

- As radial force is applied evenly to the point tips by turning a centrally-located screw, the indicators are able to measure the internal deflection of each point.

- Almost immediately upon application of the load, the indicators show that the competitor’s point flexes 600% more thanthe Royal point!

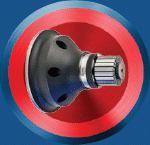

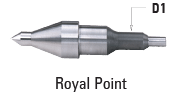

Point Analysis of 4MT Spindle Type Live Centers

D1 = Diameter of Royal Point = .603″

D2 = Diameter of Other Brand Point = .465″ Cross-Sectional Area of Royal Point = .285 sq. in.

Cross-Sectional Area of Other Brand Point = .170 sq. in.The cross-sectional area of the point on the Royal Center is 68% larger than that of the other brand, making the Royal point much more rigid and less likely to deflect under load.

Royal’s thick, beefy point offers superior rigidity, resulting in tighter part tolerances and chatter-free surface-finishes.