Royal Live Center Advantages

Royal live centers are widely regarded by top metalworking professionals as the best live centers available anywhere in the world. Each Royal live center is a finely crafted tool, incorporating the highest quality steels, bearings, lubricants and seals. Manufactured to exacting tolerances, Royal live centers are guaranteed accurate to ±0.00005″ TIR or better.

Royal Products offers a broad range of standard live center models to suit virtually all turning applications. We also design and build hundreds of custom centers each year to meet special customer requirements. Custom live centers from Royal Products are competitively priced and are held to the same high manufacturing tolerances as our standard models.

The new exclusive Royal Roto-Shield™ represents a breakthrough in live center technology, significantly increasing the effective operating life.

Royal Roto-Shield™ Technology consists of two main components:

- A live center point machined from a solid bar which incorporates a specially-shaped steel coolant slinger.

- A long-life, spring-loaded seal that is resistant to abrasion, high temperatures, and virtually all metalworking fluids.

A dramatic increase in operating life is achieved through the following effects:

- Coolant is deflected, keeping it from penetrating the center.

- Bearings are protected from harmful fines and dust.

- Seal wear is minimized.

- Lubricating grease lasts longer and retains consistency.

- High Precision Quad Bearing

- High Precision CNC Quad Bearing

- Heavy-Duty Spindle Type

- Heavy-Duty CNC Spindle Type

- The Ultimate™ Multi-Tasking Center

- High-Speed Precision

- Super Quad Extra Heavy-Duty

What Makes Royal Live Centers the Most Rigid

One of the most common misconceptions regarding live centers relates to the internal length of the rotating point.

Some manufacturers believe that a long, thin point provides more rigidity than a short, thick point. But in fact, the opposite is true.

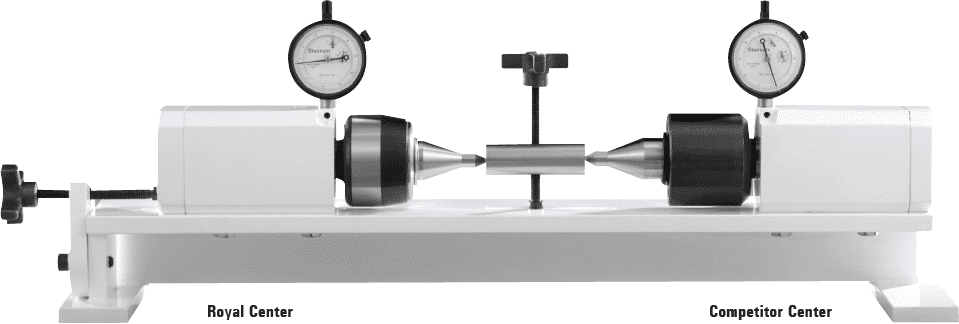

In order to verify that Royal’s short, thick point provides superior rigidity over a long, thin point, we built the test fixture pictured above.

Here’s how it works:

- Both live centers have holes drilled in their shanks corresponding to the indicator locations.

- As radial force is applied evenly to the point tips by turning a centrally-located screw, the indicators are able to measure the internal deflection of each point.

- Almost immediately upon application of the load, the indicators show that the competitor’s point flexes 600% more thanthe Royal point!

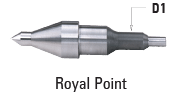

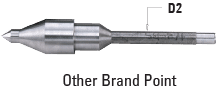

Point Analysis of 4MT Spindle Type Live Centers

D1 = Diameter of Royal Point = .603″

D2 = Diameter of Other Brand Point = .465″Cross-Sectional Area of Royal Point = .285 sq. in.

Cross-Sectional Area of Other Brand Point = .170 sq. in.The cross-sectional area of the point on the Royal Center is 68% larger than that of the other brand, making the Royal point much more rigid and less likely to deflect under load.

Royal’s thick, beefy point offers superior rigidity, resulting in tighter part tolerances and chatter-free surface-finishes.