Royal I.D. Workholding Systems

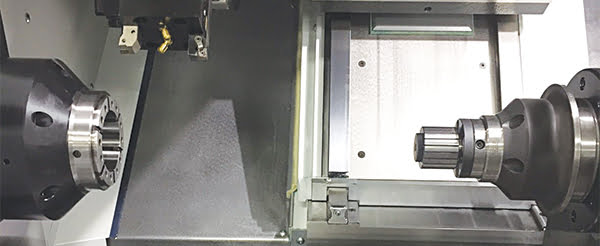

Shown here, a long casting is gripped via the I.D. bore so the full O.D. can be machined in a single operation.

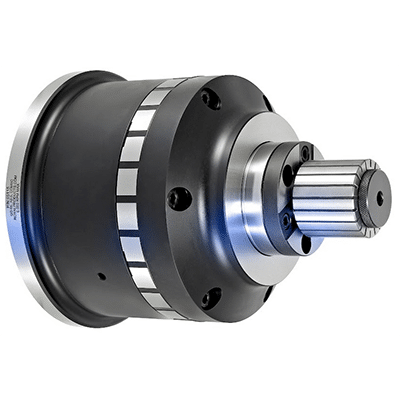

Royal’s line of I.D. Workholding Systems provides a wide range of off-the-shelf solutions for many common turning, milling, and grinding applications.

Our unique modular design covers a standard gripping range from 0.5” to 3.25”, with specials available up to 25”. Sleeves offer parallel expansion for maximum rigidity, and accuracy is guaranteed to ± 0.0005” TIR.

I.D. Gripping is Often Overlooked as a Workholding Option, Yet in Many Situations it is the Best Choice

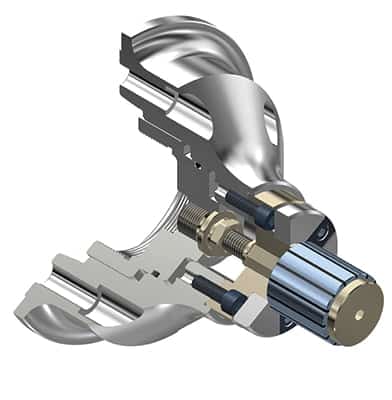

- A part’s full length can be turned in a single operation, guaranteeing perfect concentricity of all O.D. features.

- I.D. gripping offers an alternative to gripping on a finished O.D. surface, reducing the risk of part damage.

- For many parts, the engagement-length of an internal bore can be greater than what is available for external gripping, resulting in superior rigidity and torque transmission.

- I.D. systems provide optimal tool clearance, making them a great option for machines with live tooling.

Perfect Combination – A Royal Quick-Grip™ CNC Collet Chuck on the main spindle and a Royal CNC I.D. Workholding System on the sub.