Royal Custom I.D. Workholding

In order for Royal’s engineering team to make the best recommendation for your specific application, a number of parameters must be considered. If you would like our input on an I.D. workholding system that is optimized for your needs, please take a minute to consider the information outlined below and provide a solid model or drawing of your part that visually identifies these parameters.

When a standard off-the-shelf I.D. workholding system won’t quite work for your application, Royal has the expertise to design and build custom systems that are optimized for your requirements.

Below are some examples of some of the more common custom systems that we regularly supply.

Dual-Sleeve

Typically starting at $12,500

- Long parts that need extra support.

- Very aggressive machining – sometimes incorporates knurled sleeves for castings and forgings.

- Large diameter-to-length ratios.

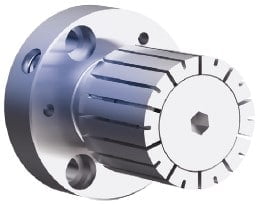

“Pressure Angle” Design

Typically starting at $4,600

- Parts with short or blind bores.

- Very aggressive machining.

- Note that with this design, the head of expanding rod is recessed behind sleeve face to maximize grip-length.

- This design applies extra gripping torque along its length to keep the workpiece firmly seated.

Extended Sleeve

Typically starting at $4,900

- Long parts that need extra support.

- Large diameter-to-length ratios.

- Great for thin-wall cylinder applications – load is distributed over a larger area to reduce risk of distortion.

Please keep in mind that in addition to the above systems, many other custom solutions/features are also available, including:

- Part ejectors

- Part confirmation

- Non-round bores

- Splined sleeves

- Radial orientation

- Positive-drive pins

- Center hole for tailstock support

- Custom locators

- Large diameters – up to 24”

- Surface-treated sleeves

- Knurled sleeves for castings and forgings

- Wide-range sleeves – to clear a small bore and expand into a larger bore

Custom I.D. Workholding Request

The more info you supply – the better we will be able to help you.