Royal QG Combo Chuck

Easily switch between O.D. and I.D. applicationsThe Best of Both Worlds

No Need to Ever Change Your Chuck Again

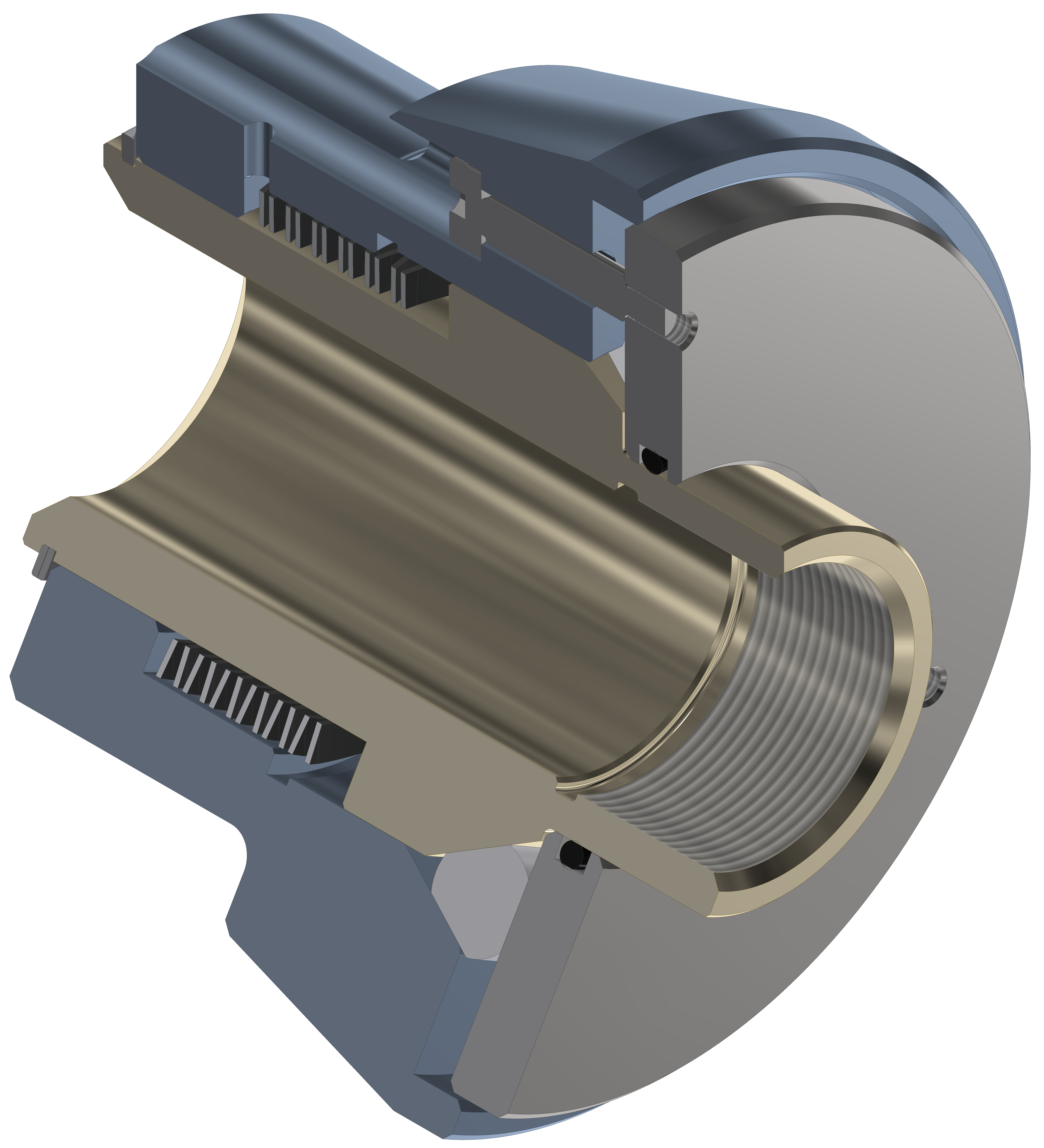

The Royal QG Combo Chuck represents the next generation of our best-selling QG-65 Accu-Length™ CNC Collet Chuck - it’s both a Quick-Grip™ Collet Chuck and an I.D. Workholding System All-in-One!

- At its core, this is a Quick-Grip™ Accu-Length™ Collet Chuck, and because there is no z-axis movement of the collet or workpiece, the chuck is perfectly suited for both main and sub-spindle applications.

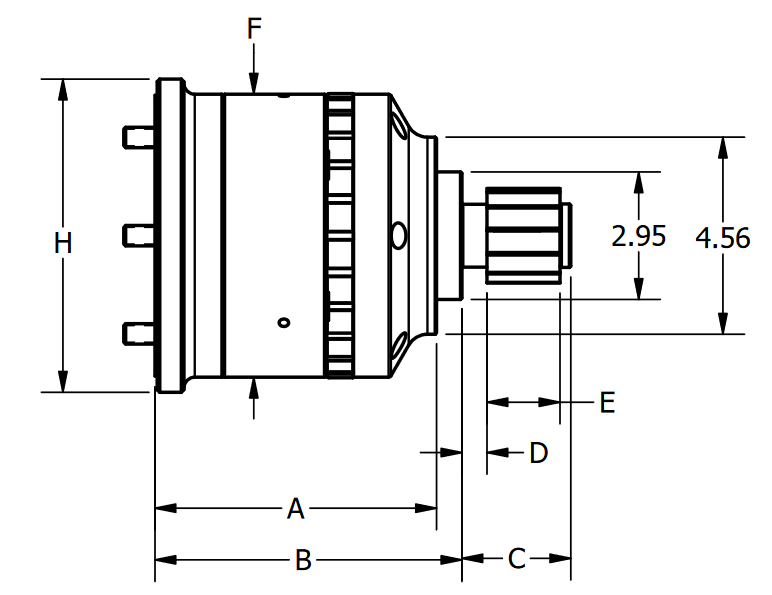

- The chuck can also be quickly converted to an I.D. workholding system simply by attaching the nose cap and mandrel. Changeover time takes just minutes.

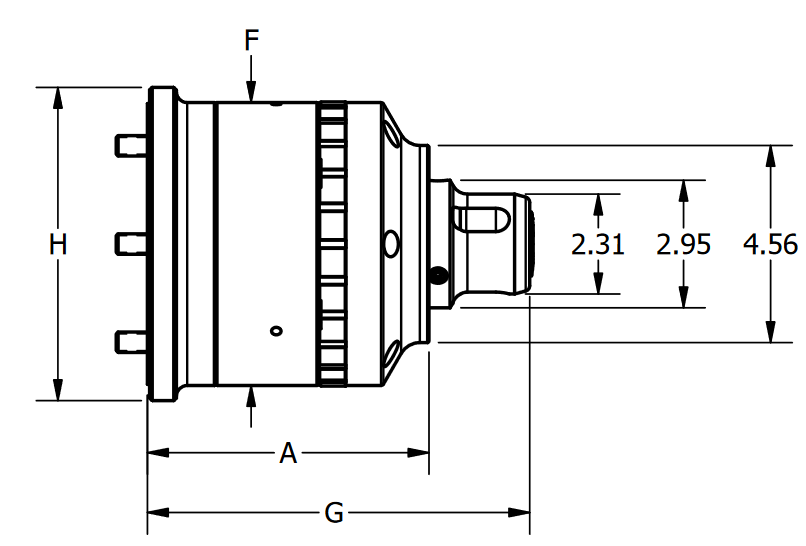

- For very small diameter work, a 5C collet nose is also available (pullback actuation).

Accu-Length™ Operation – A Very Important Royal Advantage!

Unlike other combination chucks that are based upon a pullback collet design, the Royal QG Combo Chuck is modeled on our Accu-Length™ design, ensuring precise part transfers from main to sub with no risk of z-axis part movement. This makes the Royal QG Combo chuck a much better solution for sub-spindle applications compared to the pullback models offered by others.

Lightning-Fast Collet Changes

Changning collets on a Royal Quick-Grip™ collet chuck takes just a few seconds. A unique hook and groove design for securing the collet is used instead of traditional threads.

Widest Collet Gripping Range

With a gripping range of 0.062” per collet, you don’t need to worry if your stock is off-size.

Parallel Workpiece Gripping

With all Royal QG Collet Chucks, the collet segments always remain parallel to the workpiece for full length part engagement, enabling much more aggressive chip removal.

Heavy-Duty Construction

All chuck components, except for the drawtube connector, are hardened to Rc 61-63 for high rigidity and durability.

Unlike other combination chucks that are based upon a pullback collet design, the Royal QG Combo Chuck is based on our Accu-Length™ design, ensuring precise part transfers from main to sub with no risk of z-axis part movement. This makes the Royal QG Combo chuck a much better solution for sub-spindle applications compared to the pullback models offered by others.

An included anodized aluminum ring protects the precision locating taper from chip exposure when using as a conventional collet chuck.

Extreme Accuracy

Like all Royal QG Collet Chucks, accuracy is guaranteed to be within 0.0002” TIR when being used as a collet chuck, and the I.D mandrel can be dialed in to almost absolute zero when being used as an I.D. system.

The special nose cap that houses the ID mandrel is based upon a precision face/taper interface to ensure near-perfect repeatability during changeovers. The mounting taper is located on the back side of the nose and is protected from chips by an aluminum ring when the I.D. system is not being used.

Simple Installation

All Royal QG Collet Chucks include a custom-machined drawtube connector and all mounting hardware for hasslefree installation.

Coolant Slinger

The chuck body incorporates an oversized flange to protect the machine tool spindle bearings from coolant penetration.

How It Works

With our I.D.Workholding System, the mandrel is fixed to the chuck body and a tapered pin is pulled back into the sleeve to expand it.

The Royal QG Combo Chuck uses a clever motion reversal adapter that converts the push-forward action of the closing sleeve to pullback motion that actuates the I.D. system via a series of hardened wedges. Simple, effective, and extremely durable!

Note- Actuator pressure may need to be adjusted to achieve optimal clamping force.

How to Order

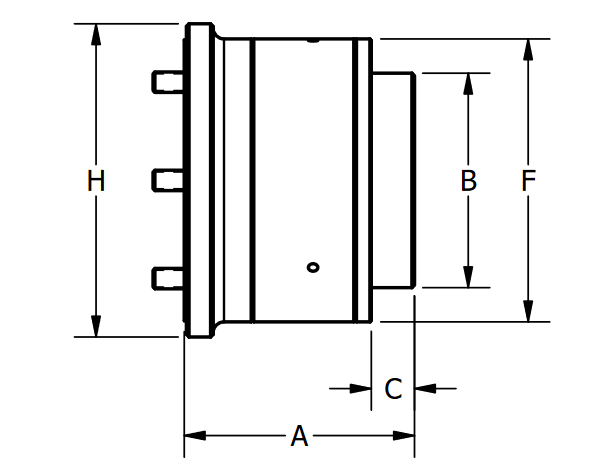

Royal QG Combo Chucks