Royal Custom Power-Block™ Workholding

The Royal Power-Block™ offers unique production-enhancing opportunities for:

- 5th-Axis Applications

- Horizontal Machining Centers

- Multi-Station Rotary-Transfer Applications

Here is a sampling of how some of our customers have greatly improved productivity with Royal Power-Blocks™.

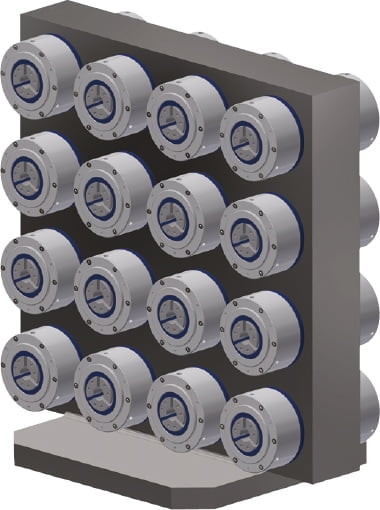

Application: Double-sided shaft-end machining on a horizontal machining center.

Capacity: 16 parts at one time.

Unique Features:

- 32 custom Small-Body Accu-Length™ Collet Fixtures mounted to a custom internally ported T-column.

- Gripping force supplied by internal die springs in each fixture.

- Pneumatically unclamped via a single intake port.

- This arrangement allows for all parts to be loaded and clamped off-line, so when the column travels into the machining center no air or hydraulic lines need to remain attached.

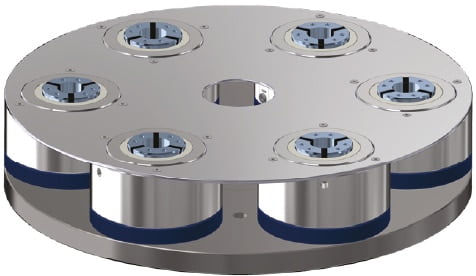

Application: “Tapered Oval” shaped part in a 5th-axis machining center.

Capacity: 4 parts at one time.

Unique Features:

- 4 standard Key-Operated Power-Blocks™ mounted to the machine tool rotary table via a custom adapter plate.

- 4 hardened and ground collets custom-machined according to the exact part profile.

- Customer experienced an increase in throughput of 236% over the multi-station vise that was previously being used.

Application: 6-station rotary-transfer machine.

Capacity: 5 parts in process at one time. 6th station used for load/unload.

Unique Features:

- 6 custom Small-Body Accu-Length™ Hydraulic Power-Block™ Fixtures mounted to a custom plate.

- 6 custom counter-bored collets for precise z-axis positioning.

- Custom chip-shield.

- Clamp/unclamp provided via a centrally located indexing hydraulic manifold (not shown).