Royal Z-Lock™ Zero-Point

Workholding System

A fast, rigid and precise zero-point workholding system for vertical, horizontal,

and five-axis machining centers.

Quick-Change Workholding For All Machining Centers

- Precision Receiver Mounts to Your Machining Center Table or Five-Axis Rotary Table

- Mount Workpieces to Top Plates Offline, Keeping Your Spindles in the Cut for Maximum Production

- Greatly Reduces Setup Times – Top Plates Interchange in Seconds with Precision Repeatability

- The Royal Z-Lock™ Keeps Your Machining Centers Making Parts – and Profits!

Simple Manual Actuation

A few turns of a hex key and it’s locked – no risk of the top plate loosening from vibration, spring wear, or air/hydraulic failure. The Royal Z-Lock™ is also a breeze to implement – no external air or hydraulic lines to install so you’ll be running parts more efficiently in no time!

Precision Repeatability

X -axis – 0.0001″

Y -axis – 0.0001″

Z -axis – 0.00005″

Extremely Powerful Clamping Force

Easily achieves up to 11,240lbs. (50kN) of clamping force – far greater than other zero-point systems (even those with a “turbo” feature). The hardened locking screw contains a large, sturdy engagement surface for failsafe operation.

Massive Locating Surface

Up to 50% greater surface area than other brands for superior stability and vibration dampening.

No “Machinist’s Touch” Required When Changing Top Plates

All stud models have been optimized to eliminate binding, making top plate changeovers a breeze.

Designed to overcome the limitations and high-cost of other zero-point systems, the Royal Z-Lock™ is a simple, precise, and affordable quick-change workholding system that offers unmatched clamping strength.

Royal Z-Lock™

An Affordable Quick-Change Workholding System

That Makes Sense for All Shops!

How it Works:

The heavy-duty clamping screw of the Royal Z-Lock™ rigidly and precisely engages the matching tapered groove in the stud, providing secure, consistent clamping force. Simple – yet powerful and reliable!

Other systems rely on spring-loaded balls to retain the stud. Over time, springs weaken, reducing the force they can apply to the balls. This can result in vibration and increased risk of the top plate disengaging under heavy machining loads.

Royal Z-Lock™

Other Systems

Easy to Understand, Easy to Use, Easy to Order!

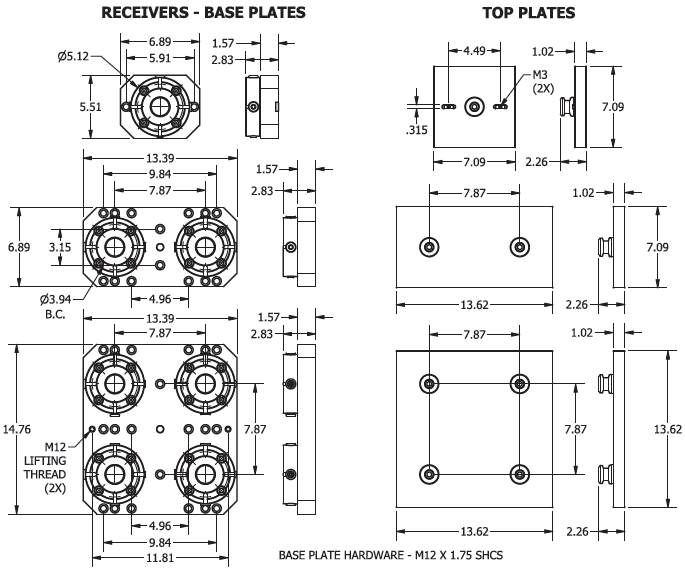

- Available from stock in single, dual, and quad configurations.

- Baseplates include multiple bolt-patterns to accommodate most common machining center T-slot spacing.

- Single receivers may be ordered without baseplates for tombstone and angle plate applications.

- Made of machinable aluminum to accommodate vises, collet fixtures, Mitee-Bite* clamps, etc. – the possibilities are limitless.

- All top plates are precision ground and include the appropriate studs pre-mounted and ready to go.

- 1″ thick to accommodate milled locating pockets up to 1/4″ deep.

- Three stud types for single, dual, and quad setups.

- Hardened and ground to handle thousands of changeovers.

- Studs are included with all top plates and are also available separately for customers who wish to use their own top plates, fixtures, or even screw them into the workpiece.

*Mitee-Bite is a registered trademark of Mitee-Bite Corporation.

| Clamping Force | 11,240 lbs. |

| X-Axis Repeatability | 0.0001″ or better |

| Y-Axis Repeatability | 0.0001″ or better |

| Z-Axis Repeatability | 0.00005″ or better |

| Receiver Height | 1.25″ |

| Receiver Diameter | 5.12″ |

| Receiver Weight | 5.6 lbs. |

| Single | 1x Positioning Stud |

| Dual | 1x Positioning Stud 1x Orienting Stud |

| Quad | 1x Positioning Stud 1x Orienting Stud 2x Clamping Studs |

No problem – Royal can manufacture whatever you need to your exact requirements. Contact us today!

Not Sure What to Order? Here’s a Popular Setup:

- 1 pc. Royal Z-Lock™ Dual Part Number 65002

(Includes two receivers mounted to baseplate) - 2 pcs. Z-Lock™ Top Plate Dual Part Number 65022 (One plate gets loaded offline while the other is working inside your machining center)

Note: Studs included with all top plates – no need to order separately.

Royal Z-Lock™ Zero-Point Workholding Systems

Description | PART NUMBER | PRICE | |

|---|---|---|---|

Z-Lock™ Single (one receiver mounted to baseplate) | $1,490.00 | ||

Z-Lock™ Dual (two receivers mounted to baseplate) | $2,570.00 | ||

Z-Lock™ Quad (four receivers mounted to baseplate) | $4,940.00 | ||

Z-Lock™ Top Plate Single (includes one positioning stud and two keys) | $485.00 | ||

Z-Lock™ Top Plate Dual (includes one positioning stud and one orienting stud) | $768.00 | ||

Z-Lock™ Top Plate Quad (includes one positioning stud, one orienting stud, and two clamping studs) | $1,490.00 | ||

Z-Lock™ Receiver Only (no baseplate) | $790.00 |

Royal Z-Lock™ Accessories and Parts

Description | PART NUMBER | PRICE | |

|---|---|---|---|

Royal Z-Lock™ Positioning Stud | $140.00 | ||

Z-Lock™ Orienting Stud | $140.00 | ||

Z-Lock™ Clamping Stud | $140.00 | ||

Z-Lock™ Receiver Bore Cover (protects receiver bore from chips when Z-Lock™ is not in use) | $98.00 | ||

Z-Lock™ Base Plate Reducer Bushing M12-M10 (for machines with narrow T-slots) | $21.00 | ||

Z-Lock™ Anti-Rotation Keys (included with Single Top Plate, not needed for Dual or Quad) | $37.00 | ||

Z-Lock™ Replacement Locking Screw | $57.00 |