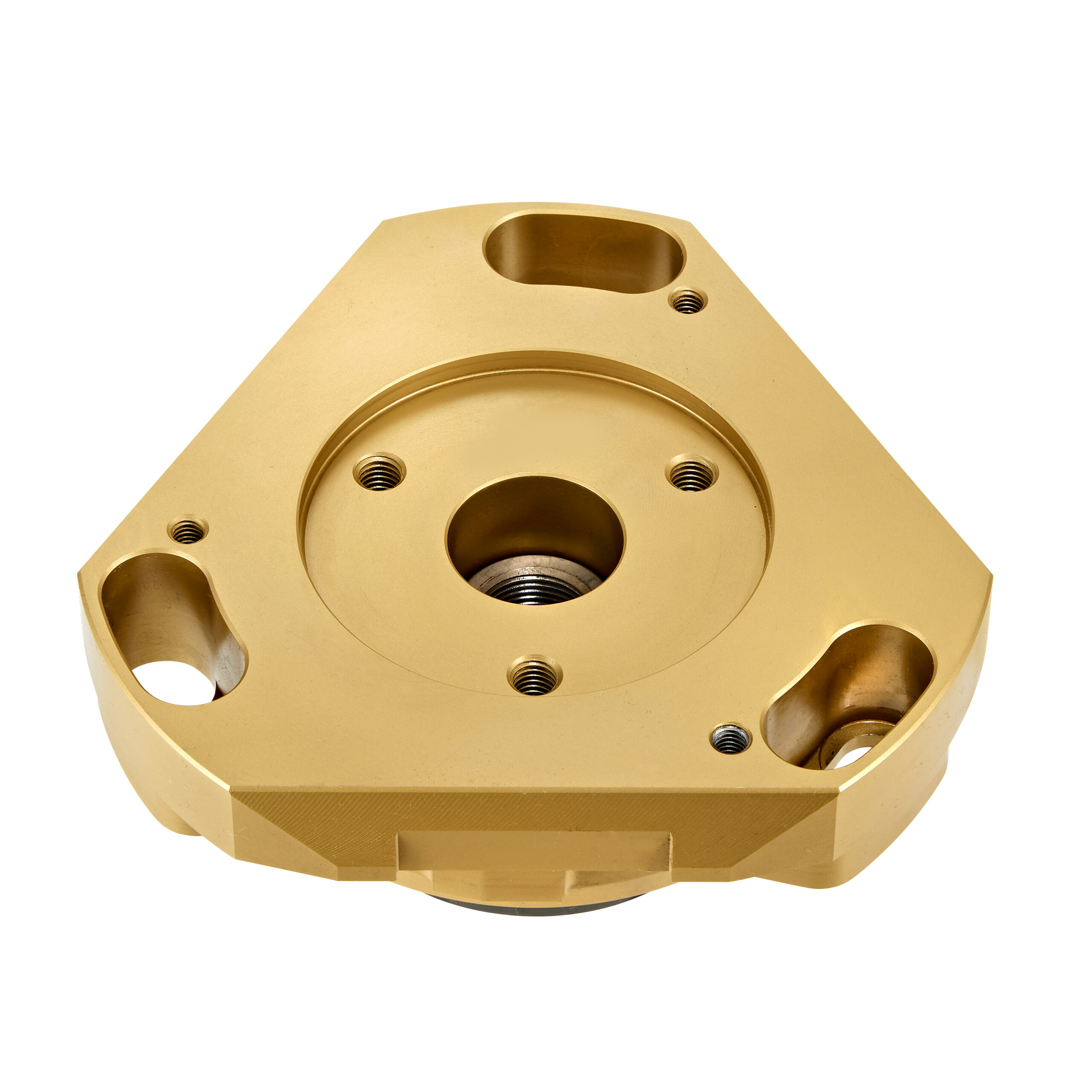

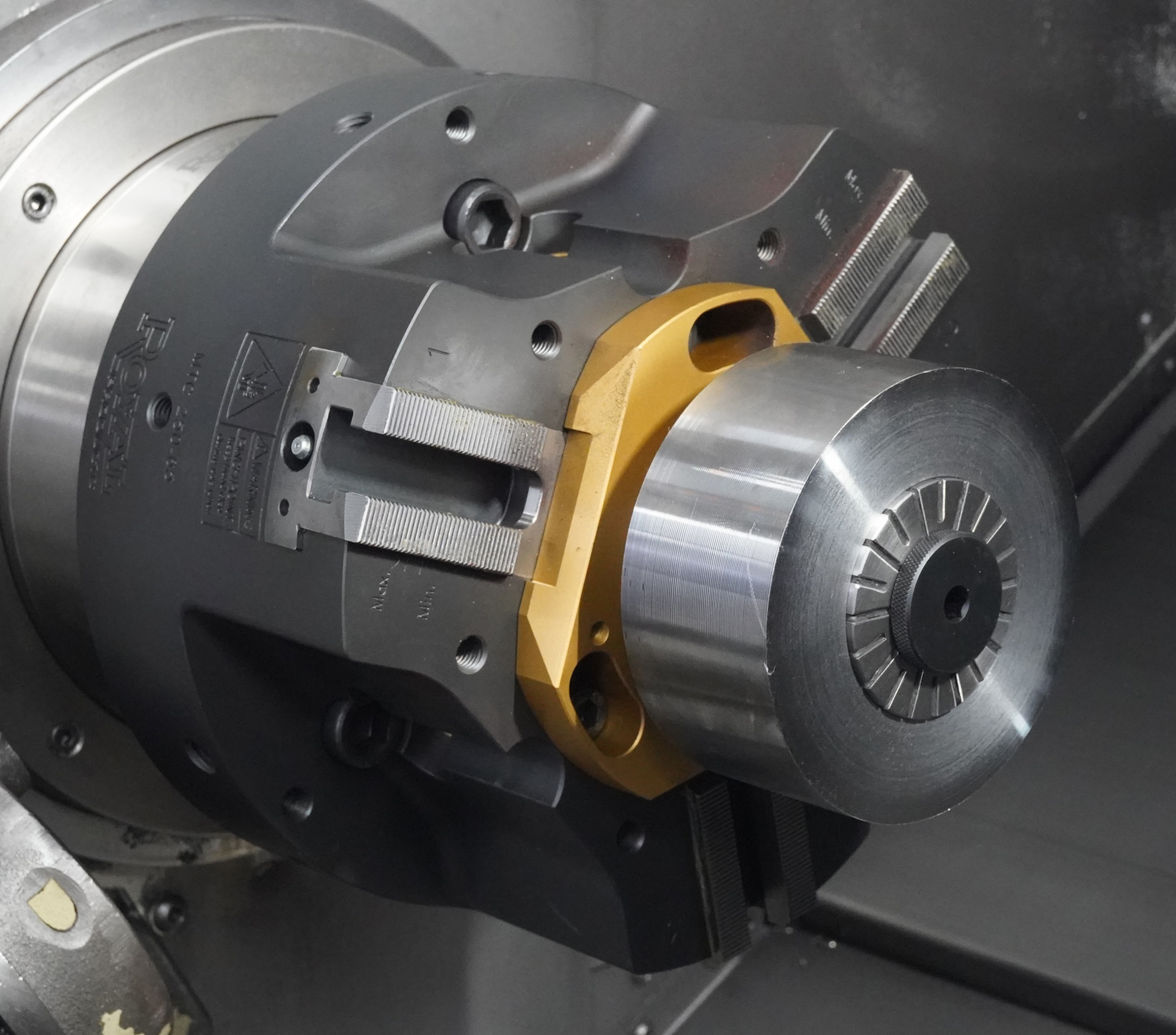

Royal MTC™ Multi-Tasking Chuck

A True All-in-One CNC Lathe Chuck

No Need to Ever Change Your Chuck Again

Switching your lathe workholding as jobs demand can be a difficult process and eats up valuable production time. But no longer! With the Royal MTC™ it’s a snap to change over between:

- 3-Jaw Chuck

- Quick-Grip™ CNC Collet Chuck

- I.D. Workholding System

- And much more…

Converting Between Jaw/Collet/I.D. Applications Takes Just Minutes and is Accomplished by Simply Swapping the Quick-Change Center Hub. The Chuck Body Never Needs to be Removed from the Lathe Spindle!

The Royal MTC™ is a Revolutionary 3-Jaw Chuck, Collet Chuck,

and I.D. Workholding System All-in-One

Royal MTC™ Advantages

- The Royal MTC™ Multi-Tasking Chuck is the only chuck you’ll ever need for your CNC lathes.

- This is a true all-in-one workholding device designed to handle large diameter parts, small diameter parts, and parts suited for I.D. gripping.

- The key to this revolutionary all-in-one design is the quick-change center hubs – there is no need to ever remove the chuck body from the lathe spindle.

- The center hubs are hardened, precision ground, and TiN coated for exceptional accuracy and wear resistance.

- Extreme rigidity is achieved through a common-sense design based upon a 3-jaw chuck with collet and I.D. capabilities - not a collet chuck with a heavy jaw-chuck hanging off the front end.

- Faster and much more cost-effective than changing out various chucks or using a “quick-change” adapter plate system that requires a crane and staging cart.

- High accuracy - jaw repeatability is 0.0002” - 0.0003”, and collet hub taper is guaranteed to be with 0.0003” TIR.

- All chuck bodies are relief milled to optimize tool clearance and reduce rotational mass.

- Available in 8”, 10”, 12”, and 15” sizes

- All Royal MTC™ Multi-Tasking Chucks include the following:

- A 3-Jaw chuck featuring industry standard 60°x1.5mm base jaws to accept a wide array of top jaws.

- A Quick-Grip™ center hub hardened and precision ground to accept Royal QG Collets.

- A thru-hole center hub to accommodate long-parts when using as a jaw chuck.

- A center cap to block chips from entering the drawtube when using the jaw chuck for slug work.

- A removeable internal workstop for use with both jaws and collets.

- A grease gun and tube of chuck grease.

- A custom-machined drawtube connector for hassle-free installation.

- Two-jaw chucks, face drivers, Morse Taper adapters, and alternative collet adapters (5C, 3J, etc.) are also available as special order.

- The center hub for I.D. work is sold separately and is compatible with all Royal I.D. mandrels, stops, and sleeves.

Easy Single Part Number Ordering

The following items are included with every Royal MTC™ Multi-Tasking Chuck:

- A 3-Jaw chuck featuring industry standard 60°x1.5mm base jaws to accept a wide array of top jaws.

- A Quick-Grip™ center hub hardened and precision ground to accept Royal Quick-Grip™ Collets.

- A thru-hole center hub to accommodate long-parts when using as a jaw chuck

- A center cap to block chips from entering the drawtube when using the jaw chuck for slug work.

- A removeable internal workstop for use with both jaws and collets.

- A center hub removal tool

- A grease gun and tube of chuck grease.

- A hardened and ground backplate to suit your particular lathe’s spindle nose (not shown).

- A custom-machined drawtube connector for hassle-free installation

Royal MTC™ Multi-Tasking Chucks

Chuck Model | Spindle Type | Collet Type | PART NUMBER | Price | |

|---|---|---|---|---|---|

MTC-200 | A2-5 | QG-52 | $32,290.00 | ||

MTC-200 | A2-6 | QG-52 | $32,290.00 | ||

MTC-200 | 140mm | QG-52 | $32,290.00 | ||

MTC-250 | A2-6 | QG-65 | $35,620.00 | ||

MTC-250 | A2-8 | QG-65 | $35,620.00 | ||

MTC-250 | 140mm | QG-65 | $35,620.00 | ||

MTC-320 | A2-6 | QG-80 | $39,985.00 | ||

MTC-320 | A2-8 | QG-80 | $39,985.00 | ||

MTC-320 | A2-11 | QG-80 | $39,985.00 | ||

MTC-400 | A2-8 | QG-100 | $45,960.00 | ||

MTC-400 | A2-11 | QG-100 | $45,960.00 | ||

MTC-400 | A2-15 | QG-100 | $45,960.00 |

*Price includes a hardened and ground backplate up to 3” long. If your machine requires an extended backplate, we will advise and quote a special plate.

Additional Accessories

Center Hub for I.D. and 5C

- The Center Hub for I.D. and 5C workholding is designed with a 75mm recess and is compatible with all Royal I.D. mandrels and sleeves (see below), as well as our 5C Collet Adapter.

- If you currently use a different brand of I.D. workholding, it may be possible for Royal to supply a custom center hub that would enable its use with the MTC – contact us to discuss.

Lifting/Installation Tool

- The lifting/installation tool is highly recommended for fast and easy installation.

- This device affixes to the chuck body in the same manner as the center hubs do, balancing the chuck’s mass and enabling it to be easily threaded onto the machine’s drawtube.

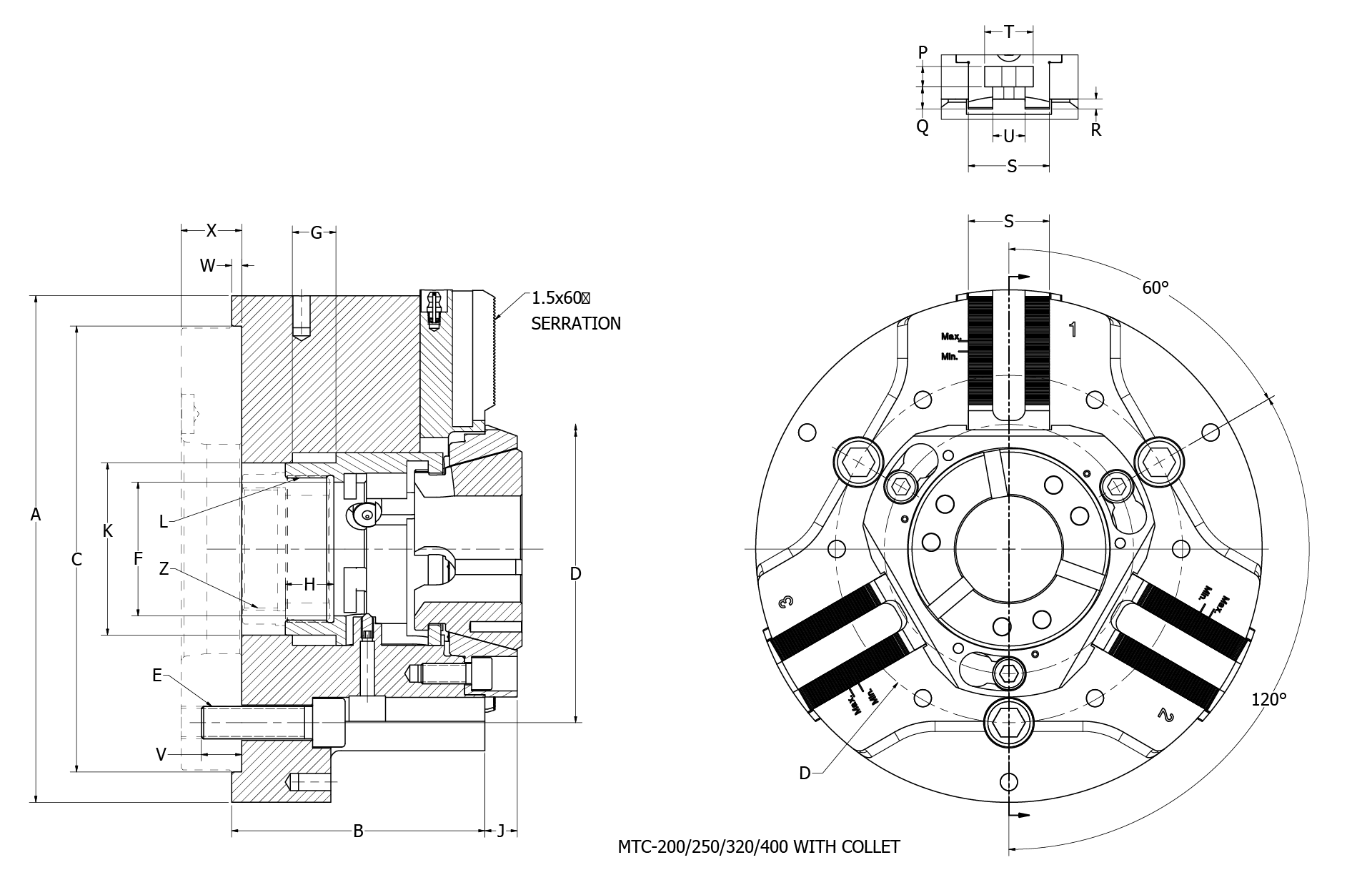

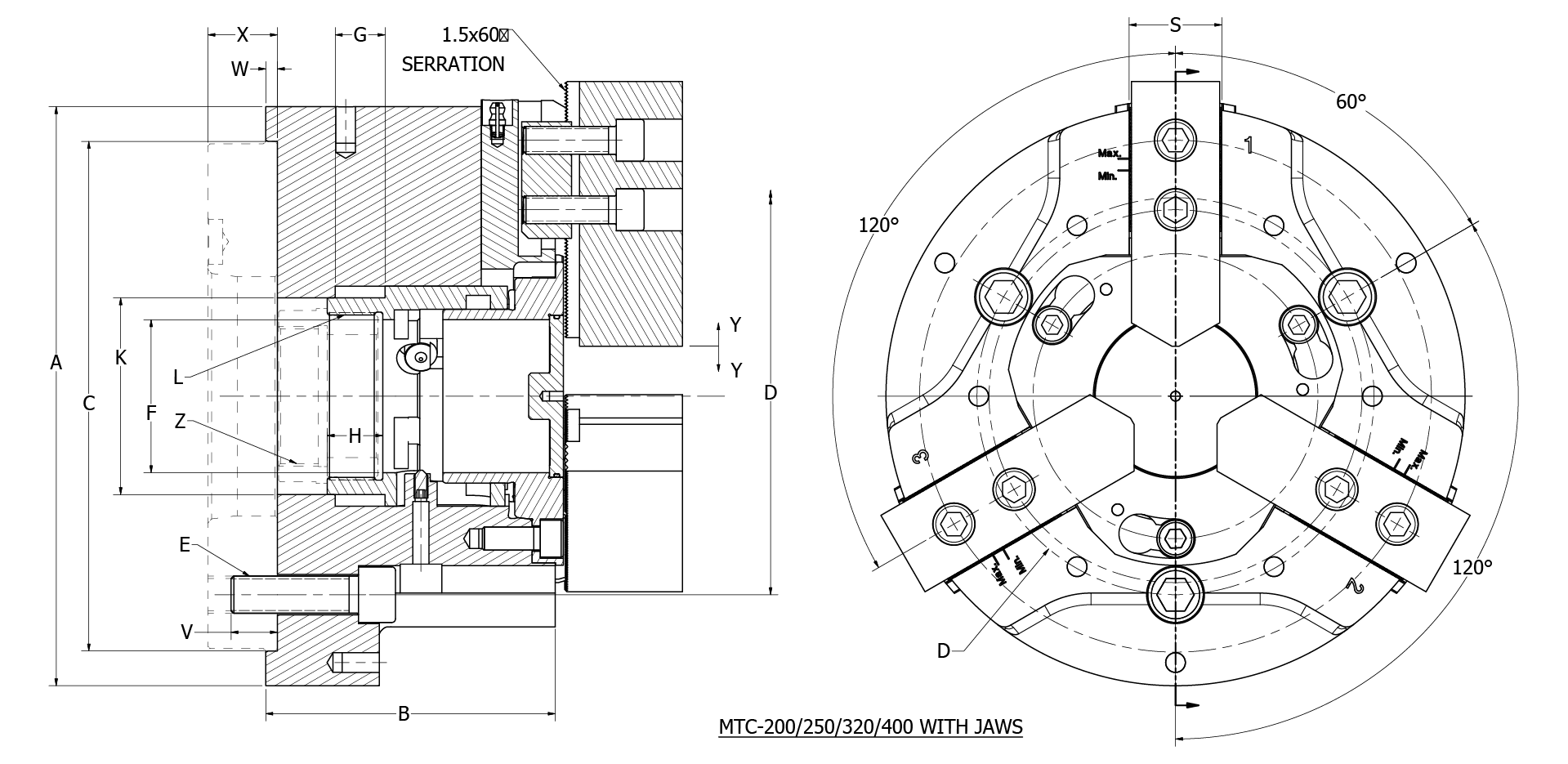

Dimensions

| MTC-200 | MTC-250 | MTC-320 | MTC-400 | |||||

|---|---|---|---|---|---|---|---|---|

| Inch | Metric | Inch | Metric | Inch | Metric | Inch | Metric | |

| A | 7.87 | 200 | 9.84 | 250 | 12.60 | 320 | 15.75 | 400 |

| B | 4.33 | 110 | 4.92 | 125 | 5.91 | 150 | 6.89 | 175 |

| C | 6.69 | 170 | 8.66 | 220 | 11.02 | 280 | 13.78 | 350 |

| D | 5.25 | 133.4 | 6.75 | 171.4 | 9.25 | 235 | 12.21 | 310 |

| E | M12 | M16 | M20 | M20 | ||||

| F | 2.09 | 53 | 2.60 | 66 | 3.19 | 81 | 4.09 | 104 |

| G (optimal) | 0.79 | 20 | 0.95 | 24 | 1.10 | 28 | 1.34 | 34 |

| G (minimum) | 0.59 | 15 | 0.71 | 18 | 0.83 | 21 | 1.00 | 25.5 |

| H | 0.91 | 23 | 0.95 | 24 | 1.10 | 28 | 1.50 | 38 |

| J | 0.43 | 11 | 0.63 | 16 | 0.63 | 16 | 0.71 | 18 |

| K | 2.95 | 75 | 3.35 | 85 | 4.13 | 105 | 5.91 | 150 |

| L | M64x1.5 | M72x1.5 | M92x2 | M130x2 | ||||

| P | 0.39 | 10 | 0.39 | 10 | 0.47 | 12 | 0.59 | 15 |

| Q | 0.43 | 11 | 0.43 | 11 | 0.47 | 12 | 0.51 | 13 |

| R | 0.20 | 5 | 0.20 | 5 | 0.20 | 5 | 0.20 | 5 |

| S | 1.58 | 40 | 1.58 | 40 | 1.77 | 45 | 2.05 | 52 |

| T | 0.95 | 24 | 0.95 | 24 | 1.19 | 30.1 | 1.19 | 30.1 |

| U | 0.63 | 16 | 0.63 | 16 | 0.83 | 21 | 0.83 | 21 |

| V | 0.79 | 20 | 0.79 | 20 | 1.02 | 26 | 0.98 | 25 |

| W | 0.20 | 5 | 0.20 | 5 | 0.20 | 5 | 0.20 | 5 |

| X | Varies | Varies | Varies | Varies | ||||

| Y | +/- 0.08 | +/- 2.0 | +/- 0.10 | +/- 2.5 | +/- 0.12 | +/- 3.0 | +/- 0.14 | +/- 3.6 |

| Z | Varies | Varies | Varies | Varies | ||||

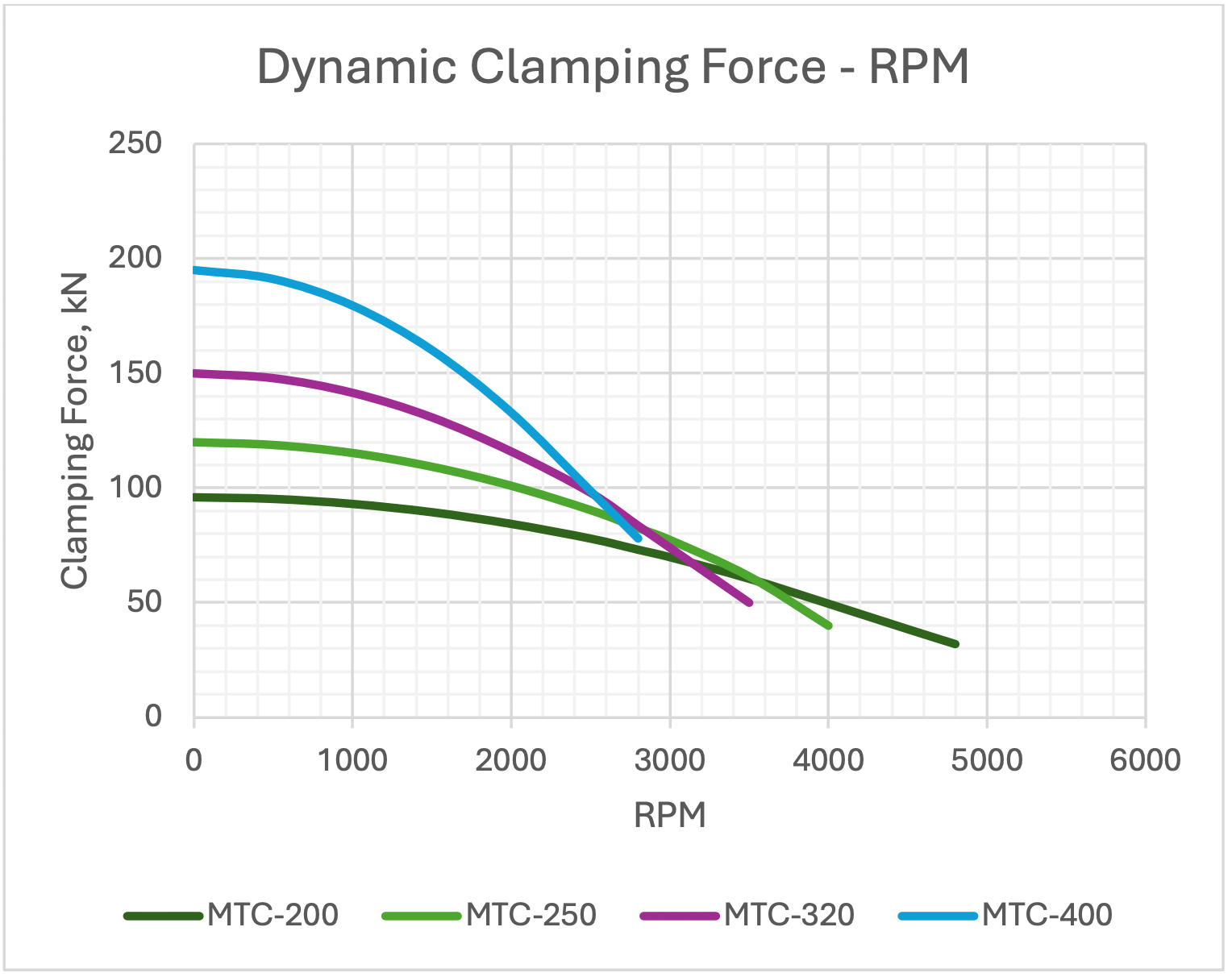

Warning: While the static clamping force of all three-jaw chucks is a function of the machine’s hydraulic actuator (piston surface area, input pressure, etc.), it is essential to understand that the dynamic clamping force acting on a workpiece is affected by additional factors such as rpm and top jaw weight. This graph represents the maximum dynamic clamping force of all Royal MTC™ chuck models throughout the stated rpm range.

Be sure to understand the relationship between input pressure and drawtube axial force for your machine’s specific hydraulic actuator and ensure that all relevant parameters are sufficient to keep workpieces safely clamped. If you have any questions or concerns regarding the safe use of this product, please contact a Royal Products applications engineer at 1-800-645-4174 before use.

MTC-200 Top Jaw Weight 4.9 lbs.

MTC-250 Top Jaw Weight 6.2 lbs.

MTC-320 Top Jaw Weight 7.9 lbs.

MTC-400 Top Jaw Weight 10.1 lbs.

Specifications

Royal MTC™ with Chuck Jaws

| MTC-200 | MTC-250 | MTC-320 | MTC-400 | |||||

|---|---|---|---|---|---|---|---|---|

| Inch | Metric | Inch | Metric | Inch | Metric | Inch | Metric | |

| Optimal Drawtube Stroke | 0.79 | 20 | 0.95 | 24 | 1.10 | 28 | 1.34 | 34 |

| Clamping Range (Jaw/Diameter) at Optimal Drawtube Stroke | 0.16/0.32 | 4/8 | 0.20/0.40 | 5/10 | 0.24/0.48 | 6/12 | 0.28/0.56 | 7.2/14.4 |

| Minimum Drawtube Stroke | 0.59 | 15 | 0.71 | 18 | 0.83 | 21 | 1.00 | 25.5 |

| Clamping Range (Jaw/Diameter) at Minimum Drawtube Stroke | 0.12/0.24 | 3/6 | 0.15/0.30 | 3.75/7.5 | 0.18/0.35 | 4.5/9 | 0.21/0.43 | 5.4/10.8 |

| Maximum Actuating Force | 9,217 (lbs.) | 41 (kN) | 11,690 (lbs.) | 52 (kN) | 14,613 (lbs.) | 65 (kN) | 19,109 (lbs.) | 85 (kN) |

| Clamping Force per Jaw | 7,194 (lbs.) | 32 (kN) | 8,992 (lbs.) | 40 (kN) | 11,240 (lbs.) | 50 (kN) | 14,613 (lbs.) | 65 (kN) |

| Total Clamping Force | 21,582 (lbs.) | 96 (kN) | 26,977 (lbs.) | 120 (kN) | 33,721 (lbs.) | 150 (kN) | 43,838 (lbs.) | 195 (kN) |

| Maximum RPM | 4800 | 4000 | 3500 | 2800 | ||||

| Weight* | 44 (lbs.) | 20 (kg) | 66 (lbs.) | 30 (kg) | 132 (lbs.) | 60 (kg) | 249 (lbs.) | 113 (kg) |

*Chuck only. Does not include backplate or top jaws.

Royal MTC™ with Collet

| MTC-200 | MTC-250 | MTC-320 | MTC-400 | |||||

|---|---|---|---|---|---|---|---|---|

| Inch | Metric | Inch | Metric | Inch | Metric | Inch | Metric | |

| QG Collet Model | QG-52 | QG-65 | QG-80 | QG-100 | ||||

| Minimum Actuating Stroke | 0.16 | 4 | 0.16 | 4 | 0.16 | 4 | 0.16 | 4 |

| Maximum Actuating Force | 9,217 (lbs.) |

41 (kN) |

10,116 (lbs.) |

45 (kN) |

11,240 (lbs.) |

50 (kN) |

14,613 (lbs.) |

65 (kN) |

| Clamping Force | 21,132 (lbs.) |

94 (kN) |

23,605 (lbs.) |

105 (kN) |

25,853 (lbs.) |

115 (kN) |

33,721 (lbs.) |

150 (kN) |

| Maximum RPM | 5500 | 4600 | 4000 | 3200 | ||||

What to Know Before you Order

In addition to the safety considerations regarding actuator force and drawtube stroke, Royal may also require some specific dimensional information for your lathe to ensure that we supply the correct backplate and drawtube connector.

We maintain an extensive machine tool database populated with thousands of actuator and drawtube specs, but sometimes changes/substitutions are made to the machine that we aren’t aware of. For safety purposes and to ensure a hassle-free installation experience, the information requested below may need to be supplied with your MTC™ order. If you have any questions, please contact a Royal Products applications engineer at 1-800-645-4174.

SPINDLE NOSE WITH CHUCK REMOVED

Note:

A drawtube sometimes unscrews from the actuator when the 3-jaw chuck is removed. Make sure drawtube is fully screwed in before taking dimensions.

![Search-Collet-Group-Header-scaled-e1739473720355[1]](https://royalproducts.com/wp-content/uploads/2025/03/Search-Collet-Group-Header-scaled-e17394737203551.jpeg)

Choose Mandrel

- Choose appropriate mandrel model according to gripping range.

- All Royal mandrels have a common precision ground interface for complete compatibility with all Royal I.D. body assemblies.

- Order body assembly, locators, and sleeves separately.

Royal Mandrels

Mandrel Model | Gripping Range | C | D | E | Max Axial Force (lbs) | Max Clamping Force (lbs) | PART NUMBER | PRICE | |

|---|---|---|---|---|---|---|---|---|---|

A | 0.479–0.640 | 1.57 | 0.57 | 0.87 | 1570 | 2670 | $1,870.00 | ||

B | 0.620 –0.901 | 1.81 | 0.59 | 1.06 | 2245 | 3820 | $1,870.00 | ||

C | 0.870 –1.151 | 2.05 | 0.61 | 1.26 | 2695 | 4580 | $1,870.00 | ||

D | 1.120 –1.651 | 2.32 | 0.60 | 1.50 | 4045 | 6875 | $1,870.00 | ||

E | 1.620 –3.276 | 2.52 | 0.58 | 1.69 | 5170 | 8785 | $1,870.00 |

Choose Part Locator

- Optional part locator bolts to the front of the mandrel and provides a precision banking surface for the workpiece to locate against.

- Order body assembly, mandrels, and sleeves separately.

Choose Expanding Sleeve

- Order expanding sleeves according to mandrel models A thru E.

- All expanding sleeves are fully sealed against coolant and chip penetration.

- Parallel grip ensures full-length part contact for optimum accuracy and grip force.

- All sleeves collapse 0.005″ below nominal ground size to ensure easy part loading and unloading.

- Order body assembly, mandrels, and locators separately

Royal Expanding Sleeves – Model A

Nominal Sleeve Diameter | Gripping Range | Part Number | PRICE | |

|---|---|---|---|---|

31⁄64″ | 0.479 - 0.499 | 47120 * Not sealed due to limited wall thickness. | $549.00 | |

1⁄2″ | 0.495 - 0.515 | 47121 * Not sealed due to limited wall thickness. | $549.00 | |

33⁄64″ | 0.511 - 0.531 | $549.00 | ||

17⁄32″ | 0.526 - 0.546 | $549.00 | ||

35⁄64″ | 0.542 - 0.562 | $549.00 | ||

9⁄16″ | 0.558 - 0.578 | $549.00 | ||

37⁄64″ | 0.573 - 0.593 | $549.00 | ||

19⁄32″ | 0.589 - 0.609 | $549.00 | ||

39⁄64″ | 0.604 - 0.624 | $549.00 | ||

5⁄8″ | 0.620 - 0.640 | $549.00 | ||

41⁄64″ | 0.636 - 0.656 | $549.00 |

Royal Expanding Sleeves – Model B

Nominal Sleeve Diameter | Gripping Range | Part Number | PRICE | |

|---|---|---|---|---|

5⁄8″ | 0.620 - 0.651 | 47130 * Not sealed due to limited wall thickness. | $598.00 | |

21⁄32″ | 0.651 - 0.682 | $598.00 | ||

11⁄16″ | 0.683 - 0.714 | $598.00 | ||

23⁄32″ | 0.714 - 0.745 | $598.00 | ||

3⁄4″ | 0.745 - 0.776 | $598.00 | ||

25⁄32″ | 0.776 - 0.807 | $598.00 | ||

13⁄16″ | 0.808 - 0.839 | $598.00 | ||

27⁄32″ | 0.830 - 0.870 | $598.00 | ||

7⁄8″ | 0.870 - 0.901 | $598.00 |

Royal Expanding Sleeves – Model C

Nominal Sleeve Diameter | Gripping Range | Part Number | PRICE | |

|---|---|---|---|---|

7⁄8″ | 0.870 - 0.901 | $598.00 | ||

29⁄32″ | 0.901 - 0.932 | $598.00 | ||

15⁄16″ | 0.933 - 0.964 | $598.00 | ||

31⁄32″ | 0.964 - 0.995 | $598.00 | ||

1″ | 0.995 - 1.026 | $598.00 | ||

1 1⁄32″ | 1.026 - 1.057 | $598.00 | ||

1 1⁄16″ | 1.058 - 1.089 | $598.00 | ||

1 3⁄32″ | 1.089 - 1.120 | $598.00 | ||

1 1⁄8″ | 1.120 - 1.151 | $598.00 |

Royal Expanding Sleeves – Model D

Nominal Sleeve Diameter | Gripping Range | Part Number | PRICE | |

|---|---|---|---|---|

1 1⁄8″ | 1.120 - 1.151 | $652.00 | ||

1 5⁄32″ | 1.151 - 1.182 | $652.00 | ||

1 3⁄16″ | 1.183 - 1.214 | $652.00 | ||

1 7⁄32″ | 1.214 - 1.245 | $652.00 | ||

1 1⁄4″ | 1.145 - 1.276 | $652.00 | ||

1 9⁄32″ | 1.276 - 1.317 | $652.00 | ||

1 5⁄16″ | 1.308 - 1.339 | $652.00 | ||

1 11⁄32″ | 1.339 - 1.370 | $652.00 | ||

1 3⁄8″ | 1.370 - 1.401 | $652.00 | ||

1 13⁄32″ | 1.401 - 1.432 | $652.00 | ||

1 7⁄16″ | 1.433 - 1.464 | $652.00 | ||

1 15⁄32″ | 1.464 - 1.495 | $652.00 | ||

1 1⁄2″ | 1.495 - 1.526 | $652.00 | ||

1 17⁄32″ | 1.526 - 1.557 | $652.00 | ||

1 9⁄16″ | 1.558 - 1.589 | $652.00 | ||

1 19⁄32″ | 1.589 - 1.620 | $652.00 | ||

1 5⁄8″ | 1.620 - 1.651 | $652.00 |

Royal Expanding Sleeves – Model E

Nominal Sleeve Diameter | Gripping Range | Part Number | PRICE | |

|---|---|---|---|---|

1 5⁄8″ | 1.620 - 1.651 | $795.00 | ||

1 21⁄32″ | 1.651 - 1.682 | $795.00 | ||

1 11⁄16″ | 1.683 - 1.714 | $795.00 | ||

1 23⁄32″ | 1.714 - 1.745 | $795.00 | ||

1 3⁄4″ | 1.745 - 1.776 | $795.00 | ||

1 25⁄32″ | 1.776 - 1.807 | $795.00 | ||

1 13⁄16″ | 1.808 - 1.839 | $795.00 | ||

1 27⁄32″ | 1.839 - 1.870 | $795.00 | ||

1 7⁄8″ | 1.870 - 1.901 | $795.00 | ||

1 29⁄32″ | 1.901 - 1.932 | $795.00 | ||

1 15⁄16″ | 1.933 - 1.964 | $795.00 | ||

1 31⁄32″ | 1.964 - 1.995 | $795.00 | ||

2″ | 1.995 - 2.026 | $795.00 | ||

2 1⁄32″ | 2.026 - 2.057 | $795.00 | ||

2 1⁄16″ | 2.058 - 2.089 | $795.00 | ||

2 3⁄32″ | 2.089 - 2.120 | $795.00 | ||

2 1⁄8″ | 2.120 - 2.151 | $795.00 | ||

2 5⁄32″ | 2.151 - 2.182 | $795.00 | ||

2 3⁄16″ | 2.183 - 2.214 | $795.00 | ||

2 7⁄32″ | 2.214 - 2.245 | $795.00 | ||

2 1⁄4″ | 2.245 - 2.276 | $795.00 | ||

2 9⁄32″ | 2.276 - 2.307 | $795.00 | ||

2 5⁄16″ | 2.308 - 2.339 | $795.00 | ||

2 11⁄32″ | 2.339 - 2.370 | $795.00 | ||

2 3⁄8″ | 2.370 - 2.401 | $795.00 | ||

2 13⁄32″ | 2.401 - 2.432 | $795.00 | ||

2 7⁄16″ | 2.433 - 2.464 | $795.00 | ||

2 15⁄32″ | 2.464 - 2.495 | $795.00 | ||

2 1⁄2″ | 2.495 - 2.526 | $795.00 | ||

2 17⁄32″ | 2.526 - 2.557 | $898.00 | ||

2 9⁄16″ | 2.558 - 2.589 | $898.00 | ||

2 19⁄32″ | 2.589 - 2.620 | $898.00 | ||

2 5⁄8″ | 2.620 - 2.651 | $898.00 | ||

2 21⁄32″ | 2.651 - 2.682 | $898.00 | ||

2 11⁄16″ | 2.683 - 2.714 | $898.00 | ||

2 23⁄32″ | 2.714 - 2.745 | $898.00 | ||

2 3⁄4″ | 2.745 - 2.776 | $898.00 | ||

2 25⁄32″ | 2.776 - 2.807 | $898.00 | ||

2 13⁄16″ | 2.808 - 2.839 | $898.00 | ||

2 27⁄32″ | 2.839 - 2.870 | $898.00 | ||

2 7⁄8″ | 2.870 - 2.901 | $898.00 | ||

2 29⁄32″ | 2.901 - 2.932 | $898.00 | ||

2 15⁄16″ | 2.933 - 2.964 | $898.00 | ||

2 31⁄32″ | 2.964 - 2.995 | $898.00 | ||

3″ | 2.995 - 3.026 | $898.00 | ||

3 1⁄32″ | 3.026 - 3.057 | $898.00 | ||

3 1⁄16″ | 3.058 - 3.089 | $898.00 | ||

3 3⁄32″ | 3.089 - 3.120 | $898.00 | ||

3 1⁄8″ | 3.120 - 3.151 | $898.00 | ||

3 5⁄32″ | 3.151 - 3.182 | $898.00 | ||

3 7⁄32″ | 3.214 - 3.245 | $898.00 | ||

3 3⁄16″ | 3.183 - 3.214 | $898.00 | ||

3 1⁄4″ | 3.245 - 3.276 | $898.00 |

*Not sealed due to limited wall thickness.

Note – sleeves larger than 2-1/2″ dia. are 0.28″ longer than dimension E and terminate flush with the face of the expanding rod.