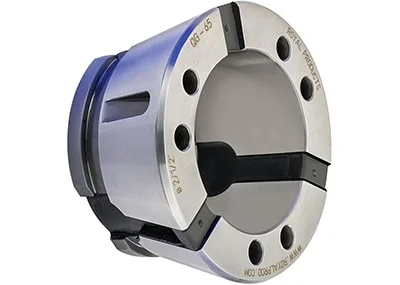

Royal Quick-Grip™ CNC Collet Chucks

The Most Advanced Collet Chucks Available for Today’s CNC Lathes

- Ten-Second Collet Changes Slash Setup Times.

- Industry-Leading Gripping Range – 0.062″/0.080″.

- Ultra-Precision Accuracy – 0.0002″ TIR Guaranteed.

- Extreme Grip Force = Most Aggressive Chip Removal Rates and Fastest Cycle Times.

- Maximum Rigidity Produces Superior Part Finishes.

- Best Tool Clearance – Critical For Live Tooling.

- Exclusive Royal Risk-Free Performance Guarantee.

- In-Stock for Same-Day Shipping.

With the Royal Quick-Grip™ CNC Collet Chuck, collet changes take just seconds. Here’s how it works:

- The unique collets are constructed of hardened steel segments securely joined together by vulcanized rubber. Each collet contains an annular hook and groove configuration on the rear section of its outer diameter.

- The installation tool incorporates steel pins that align with reamed holes on the collet face. When these pins engage the face holes and the trigger on the tool is actuated, the collet becomes temporarily compressed.

- In its compressed state, the collet can then be inserted into the collet chuck, where the hooks on the rear of the collet segments become axially aligned with a retaining groove in the chuck.

- Releasing the installation tool allows the collet to spring open, seating the hooks in the groove and drawing the matching ID/OD tapers into full, positive contact. The collet is now installed.

Ultra-Precision Accuracy – 0.0002″ or Better

While many users purchase the Royal Quick-Grip™ CNC Collet Chuck for its lightning-fast collet changes and wide gripping range, another major benefit of this system is its extreme accuracy.

With CNC collet chucks, there are several factors which affect overall system accuracy.

These include:

- Accuracy and tolerance of chuck mount (taper angle, gage line diameter, squareness of mounting flange, etc.)

- Tolerance and fit between chuck components (body to mounting adapter, closing sleeve to chuck bore, etc.)

- Accuracy and tolerance of collets (OD collet angle, bore sizing, concentricity of ID to OD, etc.)

The manufacturing processes for Royal CNC collet chucks and collets have all been fully optimized to achieve the absolute tightest tolerances and highest accuracies. While we guarantee our chucks at 0.0002″ TIR between the A-mount taper and collet chuck closing sleeve, they often run at 0.00005″ or better! Round-bore collet accuracy is also guaranteed to be within 0.0002″ TIR.

This means that out of the box, with absolutely no indicating in, you can expect to achieve a Quick-Grip™ total system accuracy of 0.0004″ TIR or better. We know of no other collet chuck manufacturer that can consistently produce such an exact level of precision.

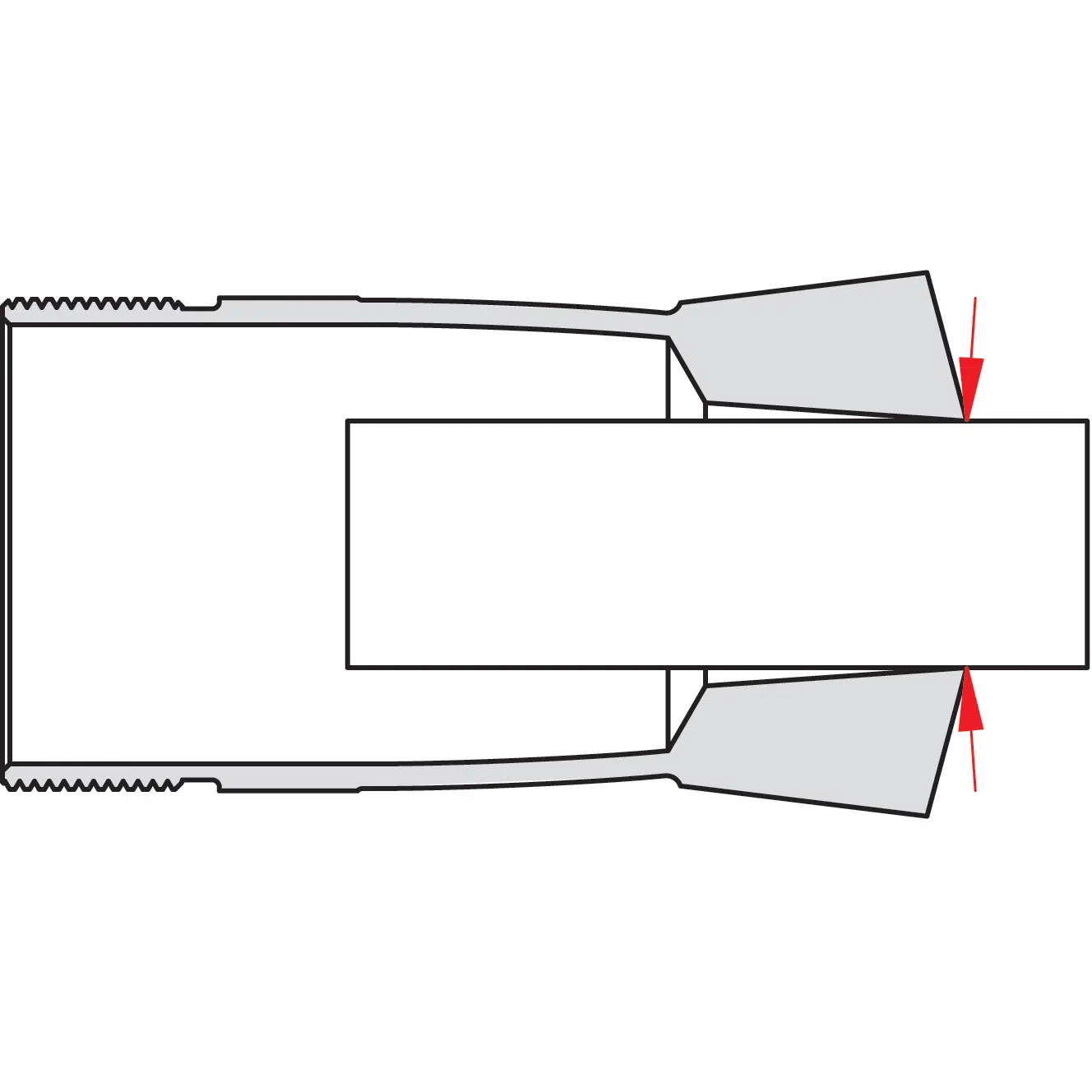

Spring-Type Collet

With a spring-type collet, unless the bore is exactly sized to the workpiece diameter there will be reduced contact, resulting in compromised accuracy and grip force.

Quick-Grip Collet

With a Quick-Grip™ collet, the segments always remain parallel to the workpiece, helping to maintain optimum accuracy and grip force.

Royal Quick-Grip™ Collets have a much wider collapse range than conventional spring collets. A spring-type collet can only be compressed by up to 0.005″ before there is a sharp drop off in both grip force and accuracy due to the changing angle of the gripping surface.

However, with the unique design of the Royal Quick-Grip™ collet, each collet segment is bonded to the adjacent segments with vulcanized rubber. This ensures that the collet segments always remain parallel to the workpiece as the collet is compressed, giving the Quick-Grip™ collet a full collapse range of .062″ (nominal diameter ± .031). For the QG-100, this range is even greater – 0.080″!

Advantages of this system include:

- The ability to compensate for oversized and undersized bar stock.

- Superior accuracy and grip force – by remaining parallel to the workpiece, each collet segment makes contact over its entire length. With old-technology spring collets, over-collapsing results in just a narrow ring of contact near the collet face.

- The wide range of the Royal Quick-Grip™ collet provides the ability to clear larger diameters in order to grip on smaller diameters. This “over the shoulder” feature offers second-op advantages over traditional spring collets.

Slash Cycle Times and Boost Throughput

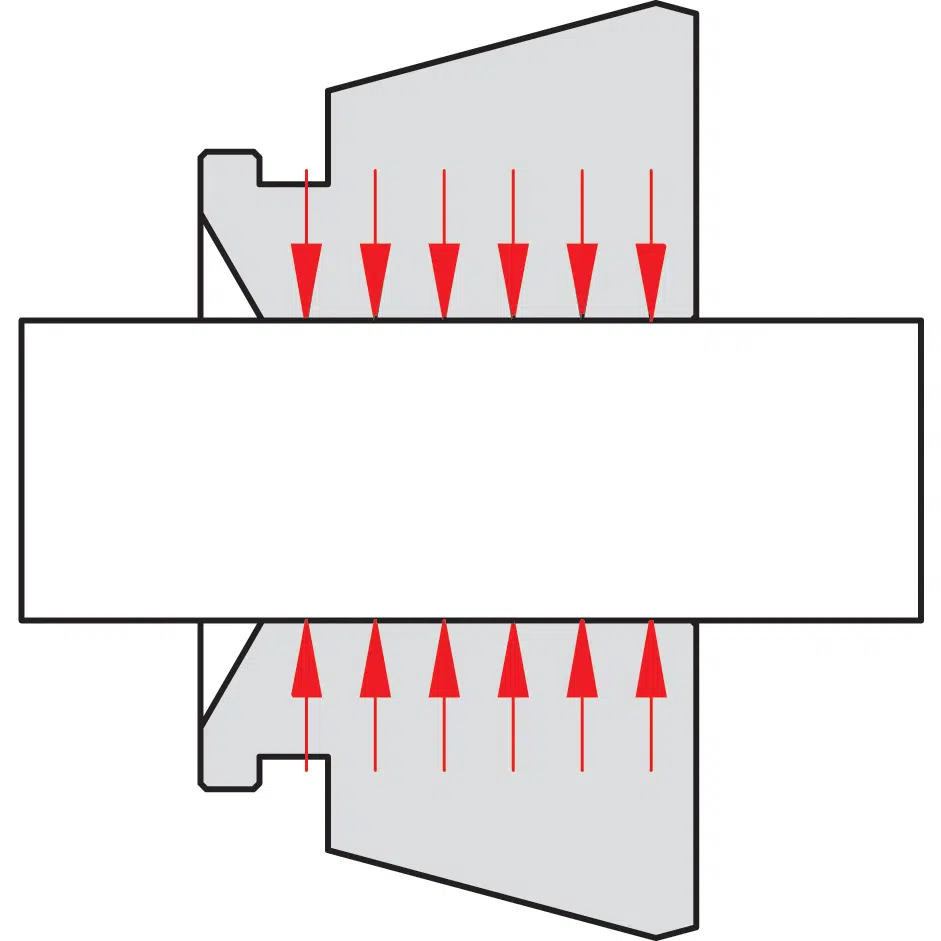

Royal Quick-Grip™ Offers Unmatched Grip Force and Rigidity

The parallel-grip functionality of Royal Quick-Grip™ Collets provides extremely high grip force by maintaining workpiece contact over the entire length of each collet segment (see image above). Additionally, the design and construction of all Royal Quick-Grip™ CNC Collet Chucks has been optimized for rock-solid rigidity.

This combination of tremendous grip force and outstanding rigidity results in something that every manufacturer strives for – the ability to drastically increase speeds, feeds and depth of cut, without sacrificing part accuracy or surface finish.

Royal Accu-Length™ CNC Collet Chucks have been optimized for tool clearance and rigidity. Short lengths maximize the usable space inside the machining envelope, while extremely compact nose diameters reduce tool interference and enable machining to take place closer to the spindle.

Compact

(Standard Length/Compact Nose Diameter)

The traditional length ensures that these chucks can accommodate most machine drawtubes, while a greatly reduced nose diameter offers the best tool clearance in the industry.

Ultra-Compact

(Compact Length/Compact Nose Diameter)

These are the smallest collet chucks available. Often mounted on sub-spindles, Royal’s Ultra-Compact CNC Collet Chucks make a great choice when maximum z-axis capacity is the primary requirement.

Extended-Length

(Longer Length/Compact Nose Diameter)

Royal stocks a few chuck models in extended-length versions to accomodate a handful of machines with limited z-axis travel. As a rule, it is usually best to choose the shortest chuck model possible for your machine.

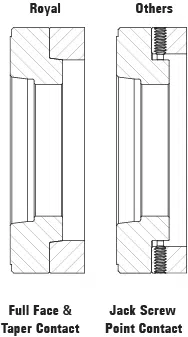

Exclusive Royal Bolt & Go™ Mounting Advantage

All Royal CNC Collet Chucks mount quickly, easily, and accurately due to our exclusive Bolt & Go™ mounting interface.

Many Royal chuck models mount directly to the lathe spindle without the need for an adapter plate. However, for models that do use a plate, a precision–ground tapered fit between the plate’s male pilot and chuck body’s female recess ensures a consistent, near-perfect fit without the need for any adjustment. This precision fit also enhances overall system rigidity by providing both face and taper contact.

Other chuck manufacturers use a less precise approach. Instead of providing a near-perfect tapered interface between the chuck body and plate, they rely on a loose fit between a male cylindrical pilot on the plate and an oversized bore within the chuck body. Because there is clearance between these two components, jack screws located around the circumference must be used to radially true-up the chuck on the plate. This process of using the jack screws and an indicator to dial out the runout each time a chuck is mounted wastes valuable production time. The rigidity of this design is also significantly less due to the limited point-contact provided by the screws against the pilot as compared to the full-contact tapered fit of the Royal Bolt & Go™ interface.

- Smarter Design

- Better Quality

- Outstanding Support

- Same-Day Shipping

- No Hassles

- Risk-Free Guarantee

In addition to providing superior quality, service, support, and deliveries, Royal CNC Collet Chucks also carry an industry exclusive risk-free performance guarantee. This no-risk guarantee allows our customers to run a collet chuck on the toughest jobs in their shop for 45-days, and if they are not 100% satisfied with its performance, we will take it back and arrange for a full refund through their distributor.

When you buy a CNC collet chuck from Royal Products, you can have complete confidence that we will not let you down. For over 75 years, Royal has been recognized as one of the most reliable and trusted suppliers in the metalworking industry. We are here for you today, and we’ll be here for you tomorrow

Every Royal CNC collet chuck is completely manufactured in our modern factory on state-of-the-art automated CNC equipment.

Every Royal CNC collet chuck is completely manufactured in our modern factory on state-of-the-art automated CNC equipment.- All chucks, sleeves, adapter plates, collets, etc., come off of our gantry-loaded multi-tasking machines complete – eliminating the accuracy and quality issues often associated with multiple setups/operations.

- All grinding takes place on precision Swiss-made CNC grinders that enable multiple features to be ground in a single setup, resulting in near-perfect tolerances and ensuring absolute consistency from part to part.

- Royal Products is an ISO9001-2015 registered company dedicated to continuous improvement. Every process is documented and followed down to the smallest detail for consistent quality – every time.

Big Benefit #9

Outstanding Support

- Royal’s knowledgeable team of applications engineers makes it very easy for you to do business with us. When you call Royal, the person you speak with will be a workholding expert, and if we can’t offer you the best solution for your application, we’ll do our best to recommend a company that can – even if it’s a competitor!

- Royal CNC Collet Chucks are sold through a select network of the country’s top industrial and machine tool distributors. We also have strong relationships with all of the major machine tool builders and importers to make sure that our products seamlessly interface with their machines.

- With over forty factory-trained account managers strategically located throughout North America, our highly-qualified field support team is always ready and willing to serve you.

Royal maintains a fleet of fully-equipped mobile showrooms designed to bring solutions to our customers’ doorsteps. Click here to schedule a visit to your company.

- All Royal CNC collet chucks include everything needed for installation, (even the hex keys). We strive to give our customers “the mint on the pillow” treatment.

- Through the past thirty years of gathering machine tool specifications and working closely with all of the major machine tool builders, Royal Products has developed a huge database of drawtube specifications, virtually eliminating the need for a customer to ever measure a machine.

- We now stock over 375 of the most common drawtube connector models, and non-stock connectors are made very quickly from semi-finished blanks.

- All Royal CNC collet chucks come packaged in specially designed heavy-gage boxes with form-fitting foam inserts to provide complete protection of all contents.

Every Royal CNC collet chuck is completely manufactured in our modern factory on state-of-the-art automated CNC equipment.

Every Royal CNC collet chuck is completely manufactured in our modern factory on state-of-the-art automated CNC equipment.