Royal Quick-Grip™ Power-Block™ Collet Fixtures

Hydraulic or Pneumatic Actuation

- Royal Power-Block™ Collet Fixtures bring the full functionality of our Quick-Grip™ CNC Collet Chucks to your vertical and horizontal machining centers.

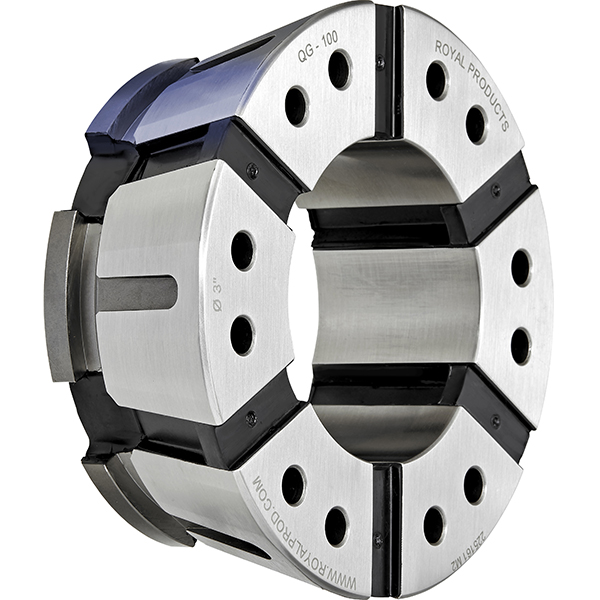

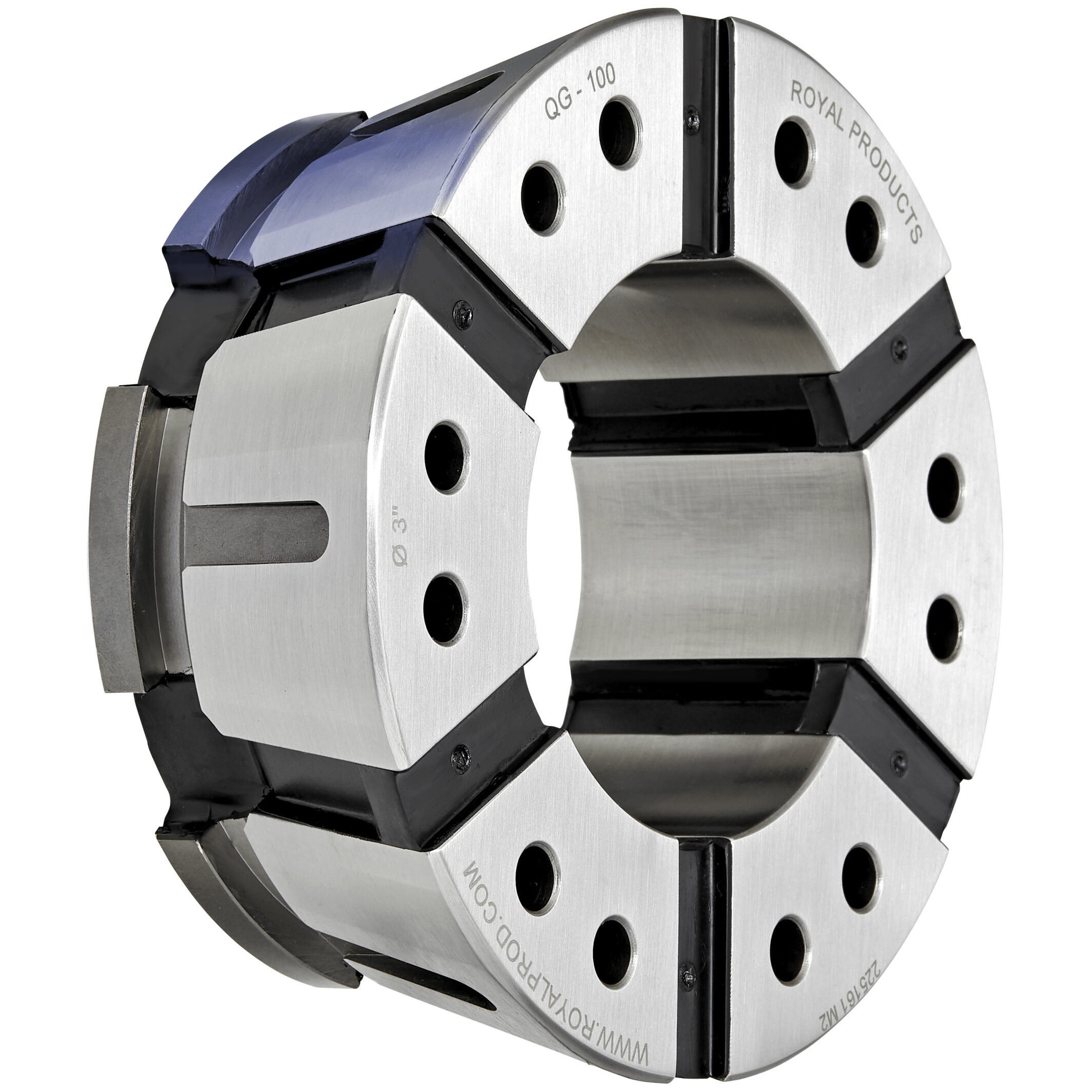

- These fixtures incorporate many of the same great features as our Quick-Grip™ CNC Collet Chucks, including ten-second collet changes and the use of parallel grip collets with a full 0.062″ clamping range (0.080″ for QG-100).

- A great alternative to traditional vises and fixtures – especially for long, thin parts, or those with asymmetrical external features.

- Units are designed to be actuated via hydraulic pressure, and may also be actuated pneumatically for lighter-duty applications.

- Engineered for use in both stationary and rotary-table applications. Caution – not for use on lathes or grinders above 60 rpm!

- Heavy-duty all steel construction with a large double-acting piston for high clamping force.

- Configured with both side and bottom ports for plumbing flexibility.

- Multiple units can be plumbed in series for single-source actuation.

- Mounting face is precision-ground for perpendicularity to centerline.

- Ideal for high-production vertical and horizontal milling applications.

Extremely Fast Collet Changes

Flexible

The face of the Royal Power-Block™ is precision-ground and includes tapped holes, enabling the use of custom stops, locators, etc.

Heavy-Duty Construction

Body and piston are hardened to Rc 61-63 for maximum rigidity and durability.

Low Maintenance

Oversized evacuation slots on all four sides enable chips to be easily flushed clear on bore-thru applications.

Tool Clearance Optimized

Slim nose diameter offers better tool clearance compared to vises and other prismatic workholding devices.

Dual-Port Actuation

All units are equipped with ports on both the side and bottom surface of the fixture, offering actuation flexibility for both fixed and rotary table applications.

Precision Mounting

Internal bore and external OD are both precision-ground, offering flexibility while ensuring accurate, repeatable mounting to plates, tombstones, etc.

Wide Gripping Range

Extreme Grip Force

The gripping segments of Royal Quick-Grip™ collets always remain parallel to the workpiece over their full length, ensuring grip force is evenly distributed. This is a significant advantage for thin-walled parts that are susceptible to crushing.

Completely Sealed

Lubricated for life, these fixtures incorporate multiple O-ring seals to prevent chips and coolant from impacting piston movement.

Custom Collet Profiles

One of the greatest advantages of this workholding system is in Royal’s ability to supply custom collet profiles for odd-shaped second-op gripping.

The Royal Power-Block™ In Action

Power-Block™ Grip Force Specifications *

| MODEL | MAX INPUT HYDRAULIC PRESSURE (psi.) |

MAX AXIAL FORCE (lbs.) |

MAX CLAMPING FORCE (lbs) |

|---|---|---|---|

| QG-32 | 1450 | 5,620 | 15,735 |

| QG-42 | 580 | 7,865 | 17,980 |

| QG-52 | 580 | 7,865 | 17,980 |

| QG-65 | 580 | 10,115 | 23,600 |

| QG-80 | 580 | 11,240 | 25,850 |

| QG-100 | 580 | 14,610 | 33,720 |

* Contact us for for pneumatic actuation specifications

When paired with a custom-profile Quick-Grip™ collet, the Royal Power-Block™ can help you optimize your workholding for parts that aren’t well-suited to traditional vises or prismatic fixtures.

Royal Quick-Grip™ Power-Block™ Collet Fixtures

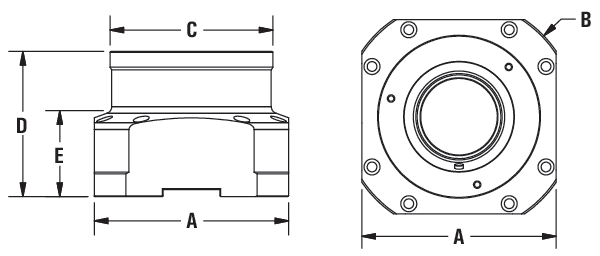

MODEL | CAPACITY (ROUND) | CAPACITY (SQUARE) | A | B | C | D | E | FIXTURE WEIGHT (lbs.) | PART NUMBER | PRICE | |

|---|---|---|---|---|---|---|---|---|---|---|---|

QG-32 | 1.29 | 0.91 | 3.15 | 4.17 | 2.95 | 3.74 | 2.09 | 6.0 | $3,065.00 | ||

QG-42 | 1.66 | 1.16 | 6.06 | 6.89 | 4.13 | 4.72 | 3.56 | 25 | $3,655.00 | ||

QG-52 | 2.00 | 1.37 | 6.06 | 6.89 | 4.13 | 4.72 | 3.56 | 25 | $3,655.00 | ||

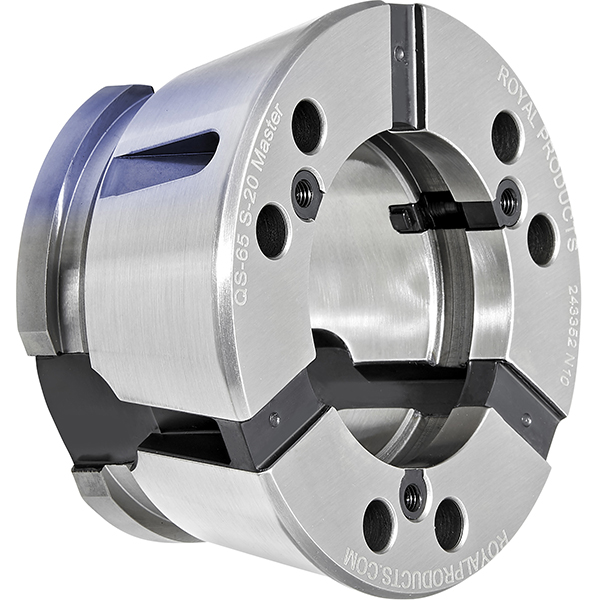

QG-65 | 2.66 | 1.78 | 6.85 | 8.27 | 4.92 | 5.12 | 3.36 | 33 | $3,940.00 | ||

QG-80 | 3.28 | 2.03 | 7.34 | 8.46 | 6.30 | 5.12 | 3.00 | 38 | $4,430.00 | ||

QG-100 | 4.03 | 2.78 | 9.02 | 10.63 | 8.46 | 5.51 | 3.38 | 66 | $6,090.00 |

Royal Power-Block™ QG-32 Fixture

High Density Workholding for Machining Centers- Royal Power-Block™ Collet Fixtures bring the full functionality of our Quick-Grip™ CNC Collet Chucks to your vertical and horizontal machining centers – Now available in compact QG-32 sizing.

- Actuated by either air or hydraulics.

- Booster cylinder available for extra clamping force.

- Compact footprint enables close ganging for multi-part applications in condensed spaces.

Power-Block™ Risers

- These risers are designed specifically for Royal Power-Block™ Hydraulic Collet Fixtures and have multiple uses, including:

- Raising the fixture height for improved 5th-axis accessibility.

- Enhancing chip evacuation for thru-hole machining applications.

- Surface ground within 0.0002” parallelism.

- Manufactured from semi-hard 4140 steel for toughness, yet it is still easily machinable for customization.

- Thickness held within 0.0005” tolerance for accurate interchangeability.

- Tapped center hole enables easy installation of a depth stop.

- 20mm wide keyway on bottom surface provides secure engagement with machining center tables and rotary tables.

- Flexible mounting:

- Milled flats allow for the use of hold-down clamps.

- Bolt directly to the machine table.

- Secure with T-nuts.

- Risers also available for Royal Key-Operated Power-Block™ Fixtures. Please contact one of our applications engineers for information.

- In stock for same-day shipping.

Royal Power-Block™ Risers

*Riser only. Order Power-Block™ and collets separately.ROYAL ULTRA-PRECISION QUICK-GRIP™ COLLETS

Why Do Top Manufacturers Insist on Royal Quick-Grip™ Collets?

Industry-Leading 0.062" (0.080” for QG-100) Gripping Range Covers More Diameters with Fewer Collets

Ultra-Precision Accuracy – 0.0002" TIR or Better

Vulcanization Guaranteed for Life

Parallel-Grip Maintains Full-Length Part Engagement

Exceptional Grip-Force Enables Very Aggressive Cutting

Exclusive Royal Risk-Free Performance Guarantee

Fast Delivery on Custom Shapes and Sizes

Special Slot Relief Grinding Eliminates "Collet Popping" and Minimizes Chuck Wear

These Extremely Advanced Collets Will Revolutionize Your Workholding

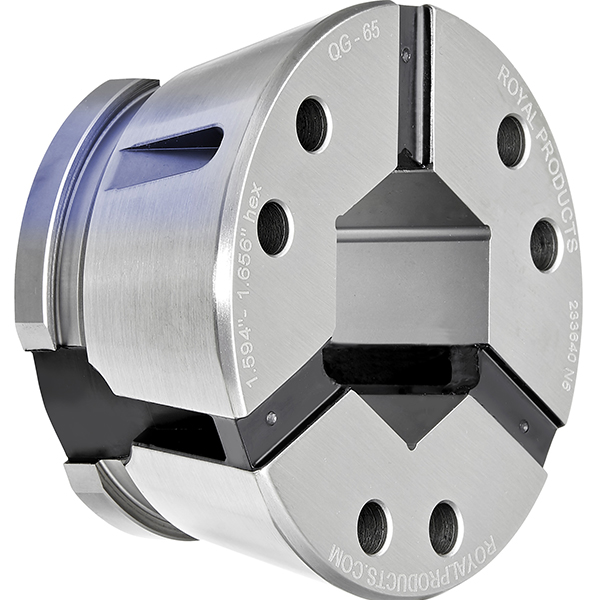

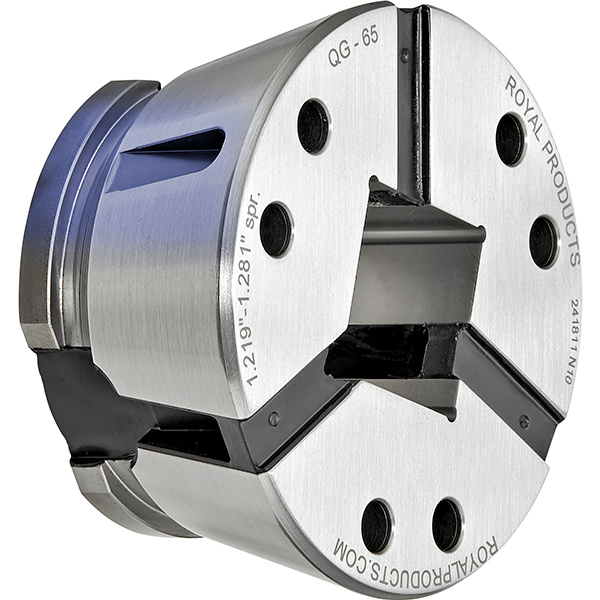

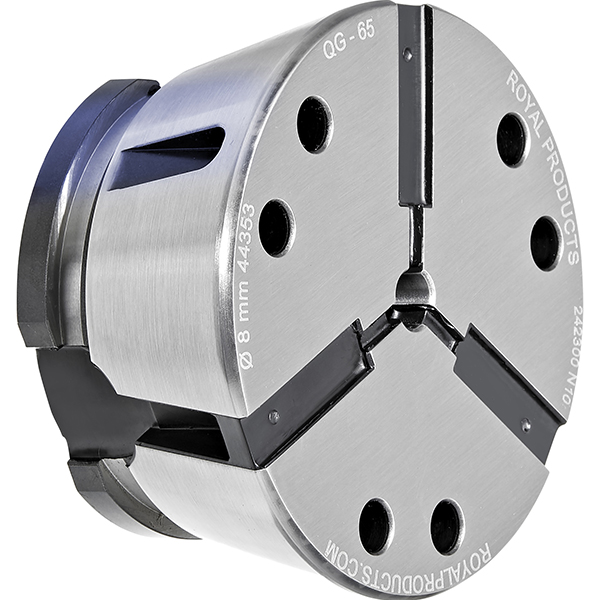

- Industry-leading 0.062" Gripping Range (0.080" for QG-100) – greater than other quick-change collets on the market and more than 12X that of traditional spring collets.

- Royal Quick-Grip Collets are precision-ground to nominal size, with a gripping range of ±0.031" (0.040” for QG-100) to handle undersized/oversized stock.

Example – a ½" QG-65 collet is ground to 0.500" dia., and can hold any part ranging in size from 0.469" – 0.531" dia. - Ultra-Precision Accuracy – 0.0002" TIR or better guaranteed on round-bores. Total system accuracy (chuck + collet) guaranteed to 0.0004" or better.

- All Royal Quick-Grip™ Collets are designed for minimal projection beyond the chuck face (≤ 0.020") for optimum rigidity and machine work-zone utilization.

- All models have a smooth gripping surface, but round-bores are also available from stock in a double-serrated version for very aggressive first-op machining.

- Vulcanized rubber between the hardened steel collet segments provides outstanding protection against coolant and chip penetration, and Royal’s advanced vulcanization process carries a lifetime guarantee against failure.

- Collets can be counter-bored for increased capacity.

- S-type master collets available for QG-65 and QG-80 chuck models.

- Royal Quick-Grip™ Collets are compatible with some other brands of quick-change chucks, but note that the QG-80 and QG-100 models have a six-slot design (for increased gripping torque) that requires the use of a Royal installation tool. Call us to verify compatibility.

- Custom sizes and shapes available as quick-ship specials. Collet segments can also be carbide-coated for extremely harsh applications. Contact one of our applications engineers at 1-800-645-4174 to discuss your requirements.

Order Today – Have it Tomorrow