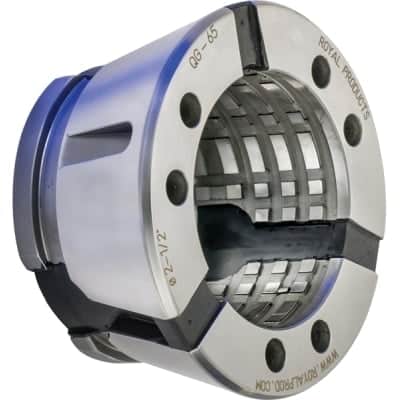

Royal Quick-Grip™ Pull-to-a-Stop CNC Collet Chucks

Bolt & Go™

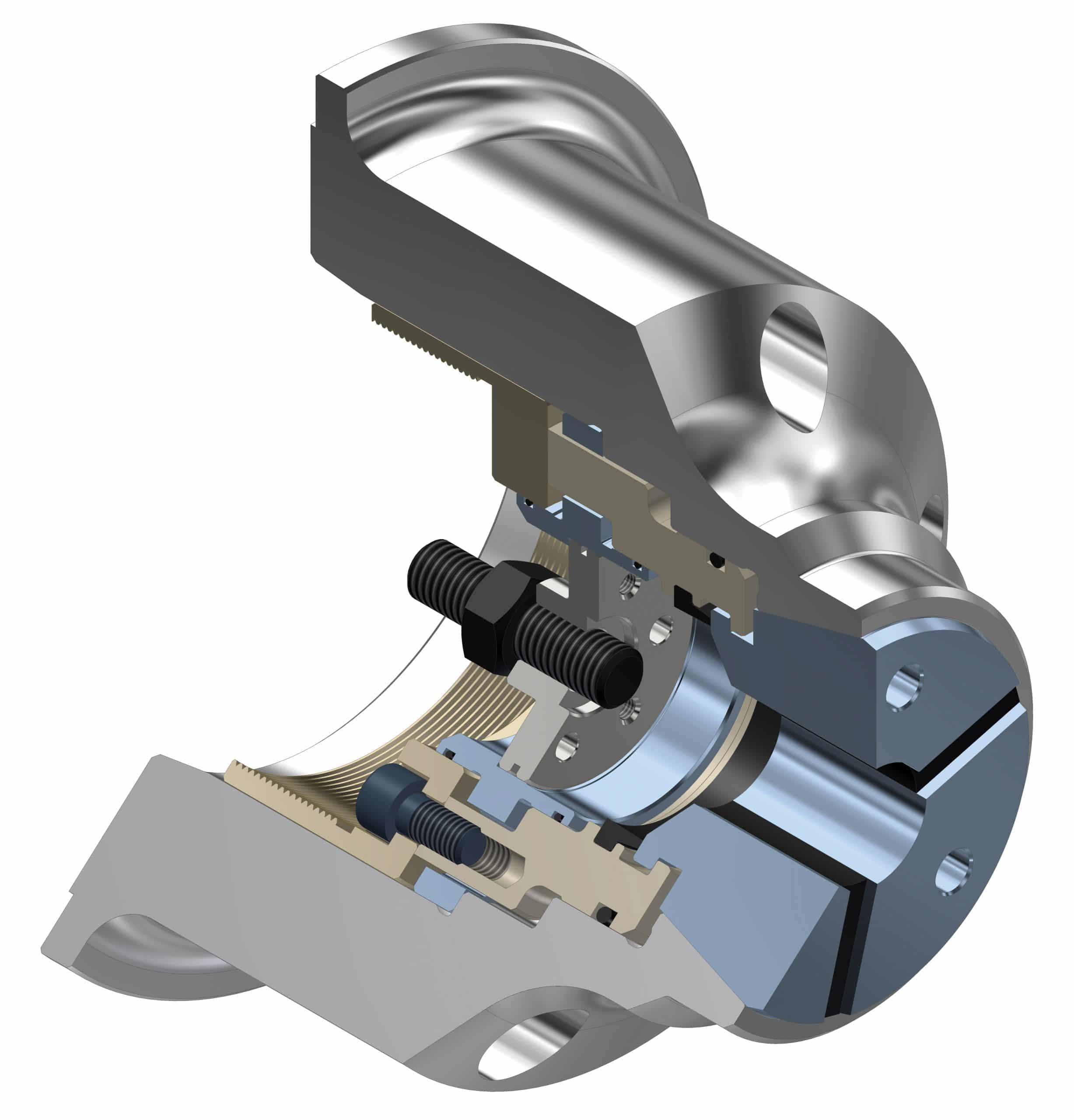

Our exclusive Bolt & Go™ mounting feature is standard on all Royal Quick-Grip™ Collet Chuck models. Bolt & Go™ enables chucks to be mounted very quickly and ensures maximum accuracy and rigidity. Click here for additional information.

Completely Sealed

Completely Sealed Lubricated for life, these chucks incorporate multiple O-ring seals to keep contaminants out and prevent chip pack-up on bore-thru applications.

High RPM

All Royal Quick-Grip™ Collet Chucks are balanced by design for high-speed operation, and can often be run at higher speeds than conventional 3-jaw chucks because they are less affected by centrifugal force.

Coolant Slinger

All bodies incorporate an oversized flange to protect the machine tool spindle bearings from coolant penetration.

Shortest Length

Royal Quick-Grip™ CNC Collet Chucks are among the shortest chucks available, providing maximum work envelope utilization. This is especially important for smaller machines with limited z-axis travel.

Note – Collets and installation tool sold separately

Extremely Fast Collet Changes

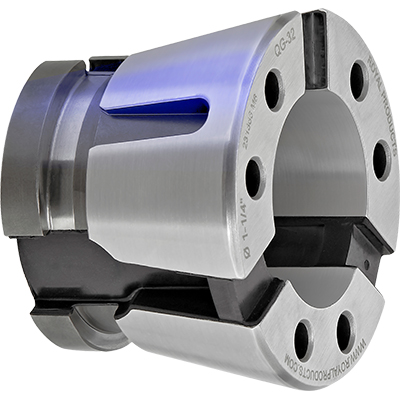

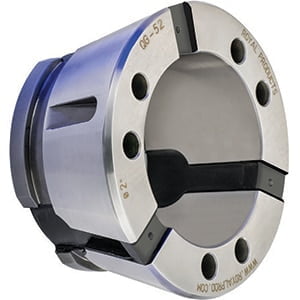

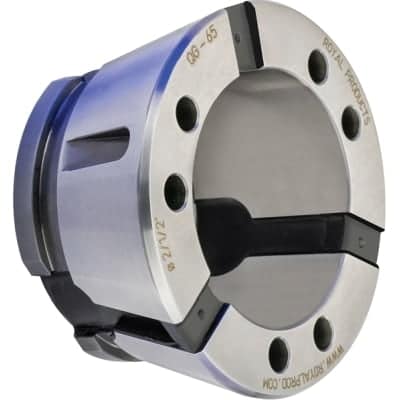

Changing collets on a Royal Quick-Grip™ CNC Collet Chuck takes just a few seconds. A unique hook and groove design for securing collets is used instead of traditional threads.

Wide Gripping Range

Royal Quick-Grip™ Collets have a 0.062" gripping range (±0.031"), enabling them to accommodate undersized and oversized bar stock. This range is even larger for the QG-100 - 0.080".

High Accuracy

Royal Quick-Grip™ CNC Collet Chucks are very accurate – runout on the closing angle is guaranteed to be within 0.0002" TIR.

Low-Profile

Royal Quick-Grip™ CNC Collet Chucks have smaller nose diameters than other quick-change collet chucks for superior tool clearance.

Collet Compatibility

Royal Quick-Grip™ Collet Chucks can sometimes utilize other brands of quick-change collets. Call Royal to verify.

Heavy-Duty Construction

All chuck components, except for the drawtube connector, are hardened to Rc 61-63 for high rigidity and durability.

Easy Installation

Royal Quick-Grip™ Collet Chucks include all mounting hardware, mounting wrenches, and a custom-machined drawtube connector to ensure hassle-free installation.

Specials

If you have a special application that goes beyond the scope of our standard line, we will be happy to design and build a custom system to meet your needs. Please contact a Royal applications engineer to discuss your requirements.

Two-Chucks In One

The Royal Quick-Grip™ Pull-to-a-Stop CNC Collet Chuck includes a removable stop for precise, consistent workpiece positioning. The pullback action of the collet draws the workpiece securely against the stop, eliminating any chance of z-axis part movement and enabling very aggressive cutting.

When thru-hole capacity is required for bar feeding applications, simply remove the stop and the chuck will function as a normal pullback-style collet chuck.

ROYAL QUICK-GRIP™ PULL-TO-A-STOP CNC COLLET CHUCKS

- Same great features as our Accu-Length™ Quick-Grip™ models, except that the collet is not fixed – it moves axially upon opening and closing.

- Adjustable stop guarantees precise, consistent z-axis part positioning and enables very aggressive cutting.

- Ideal for high-volume, robot-load applications in which the part needs to locate against a shoulder and air-sensing / position confirmation is required.

- Also a great choice for any CNC lathe equipped with a servo-driven bar feeder – simply remove the included stop for full thru-capacity.

- In-stock for same-day shipping.

Royal Quick-Grip™ Pull-to-a-Stop CNC Collet Chucks

SPINDLE TYPE | COLLET TYPE | MAX CAPACITY BAR | MAX CAPACITY SLUG3 | A OVERALL LENGTH | B NOSE DIAMETER | C NOSE LENGTH | D BODY DIAMETER | E FLANGE DIAMETER | CHUCK WEIGHT (lbs.) | MAX DRAWBAR FORCE (lbs.) | MAX CLAMPING FORCE (lbs.) | MAX RPM | PART NUMBER | PRICE1 |  |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

A2-5 | QG-42 | 1.66 | 2.62 | 5.10 | 3.54 | 0.62 | 6.00 | 6.70 | 21 | 7,865 | 17,980 | 6,000 | $5,140.00 | ||

A2-6 | QG-42 | 1.66 | 2.62 | 5.50 | 3.54 | 0.62 | 6.25 | 7.45 | 25 | 7,865 | 17,980 | 6,000 | $5,140.00 | ||

A2-5 | QG-52 | 2.03 | 2.57 | 5.25 | 3.63 | 0.62 | 6.19 | 6.95 | 21 | 7,865 | 17,980 | 6,000 | $5,140.00 | ||

A2-6 | QG-52 | 2.03 | 2.57 | 5.65 | 3.63 | 0.62 | 6.19 | 7.25 | 22 | 7,865 | 17,980 | 6,000 | $5,140.00 | ||

A2-5 | QG-65 | 2.66 | 3.40 | 5.50 | 4.37 | 0.80 | 6.70 | 7.62 | 28 | 10,115 | 23,600 | 6,000 | $5,870.00 | ||

A2-6 | QG-65 | 2.66 | 3.40 | 6.00 | 4.37 | 0.80 | 6.70 | 7.62 | 29 | 10,115 | 23,600 | 6,000 | $5,870.00 | ||

A2-6 | QG-65 | 2.66 | 3.40 | 7.00 2 | 4.37 | 0.80 | 6.70 | 7.62 | 35 | 10,115 | 23,600 | 6,000 | $5,870.00 | ||

A2-8 | QG-65 | 2.66 | 3.40 | 6.40 | 4.37 | 0.80 | 7.95 | 9.45 | 45 | 10,115 | 23,600 | 6,000 | $5,870.00 | ||

A2-6 | QG-80 | 3.28 | 4.00 | 6.00 | 4.96 | 0.80 | 8.00 | 8.75 | 44 | 11,240 | 25,850 | 5,000 | $6,440.00 | ||

A2-8 | QG-80 | 3.28 | 4.00 | 6.40 | 4.96 | 0.80 | 8.00 | 9.45 | 47 | 11,240 | 25,850 | 5,000 | $6,440.00 | ||

A2-6 | QG-100 | 4.03 | 5.15 | 7.08 | 6.30 | 0.80 | 9.40 | 9.40 | 88 | 14,610 | 33,720 | 5,000 | $7,980.00 | ||

A2-8 | QG-100 | 4.03 | 5.15 | 7.33 | 6.30 | 0.80 | 9.40 | 10.75 | 95 | 14,610 | 33,720 | 5,000 | $7,980.00 | ||

A2-11 | QG-100 | 4.03 | 5.15 | 7.58 | 6.30 | 0.80 | 9.40 | 12.50 | 102 | 14,610 | 33,720 | 5,000 | $8,660.00 |

¹ Includes drawtube connector. Collets and installation tool sold separately.

² Extended-length – for use on machines where z-axis turret travel is limited.

³ Slug capacity requires counterboring of collets. See boring fixtures details.

ROYAL ULTRA-PRECISION QUICK-GRIP™ COLLETS

These Extremely Advanced Collets Will Revolutionize Your Workholding

- Industry-leading 0.062" Gripping Range (0.080" for QG-100) – greater than other quick-change collets on the market and more than 12X that of traditional spring collets.

- Royal Quick-Grip Collets are precision-ground to nominal size, with a gripping range of ±0.031" (0.040” for QG-100) to handle undersized/oversized stock.

- Example – a ½" collet is ground to 0.500" dia., and can hold any part ranging in size from 0.469" – 0.531" dia.

- Ultra-Precision Accuracy – 0.0002" TIR or better guaranteed on round-bores. Total system accuracy (chuck + collet) guaranteed to 0.0004" or better.

- All Royal Quick-Grip™ Collets are designed for minimal projection beyond the chuck face (≤ 0.020") for optimum rigidity and machine work-zone utilization.

- All models have a smooth gripping surface, but round-bores are also available from stock in a double-serrated version for very aggressive first-op machining.

- Vulcanized rubber between the hardened steel collet segments provides outstanding protection against coolant and chip penetration, and Royal’s advanced vulcanization process carries a lifetime guarantee against failure.

- Collets can be counter-bored for increased capacity.

- S-type master collets available for QG-65 and QG-80 chuck models.

- Royal Quick-Grip™ Collets are compatible with some other brands of quick-change chucks, but note that the QG-80 and QG-100 models have a six-slot design (for increased gripping torque) that requires the use of a Royal installation tool. Call us to verify compatibility.

- Custom sizes and shapes available as quick-ship specials. Collet segments can also be carbide-coated for extremely harsh applications. Contact one of our applications engineers at 1-800-645-4174 to discuss your requirements.

Why Do Top Manufacturers Insist on Royal Quick-Grip™ Collets?

Industry-Leading 0.062" (0.080” for QG-100) Gripping Range Covers More Diameters with Fewer Collets

Ultra-Precision Accuracy – 0.0002" TIR or Better

Vulcanization Guaranteed for Life

Parallel-Grip Maintains Full-Length Part Engagement

Exceptional Grip-Force Enables Very Aggressive Cutting

Exclusive Royal Risk-Free Performance Guarantee

Fast Delivery on Custom Shapes and Sizes

Special Slot Relief Grinding Eliminates "Collet Popping" and Minimizes Chuck Wear

Order Today – Have it Tomorrow

Round – Smooth

Round – Serrated

Hex

Square