Royal Filtermist Units

![]() FREE After Filter and Drum Pad Set

FREE After Filter and Drum Pad Set

Special Offer - Royal Products will include a FREE standard after filter and a FREE set of drum pads with every new Royal Filtermist unit you purchase – a value worth up to $548! For most applications, this means your first-year maintenance is on us. Order today!

| Airflow | 295 cfm |

| Fits machines with enclosure volume | Up to 80 cubic feet |

| Weight | 31 lbs. |

| Inlet Diameter | 6″ |

Unit includes all hardware for direct mounting and 5ft. of coolant return hose.

| Airflow | 560 cfm |

| Fits machines with enclosure volume | 60–120 cubic feet |

| Weight | 35 lbs. |

| Inlet Diameter | 6″ |

Unit includes all hardware for direct mounting and 5ft. of coolant return hose.

| Airflow | 900 cfm |

| Fits machines with enclosure volume | 90–180 cubic feet |

| Weight | 51 lbs. |

| Inlet Diameter | 6″ |

Unit includes 12ft. of coolant return hose.

| Airflow | 1200 cfm |

| Fits machines with enclosure volume | 120 cubic feet or larger |

| Weight | 64 lbs. |

| Inlet Diameter | 8″ |

Unit includes 12ft. of coolant return hose.

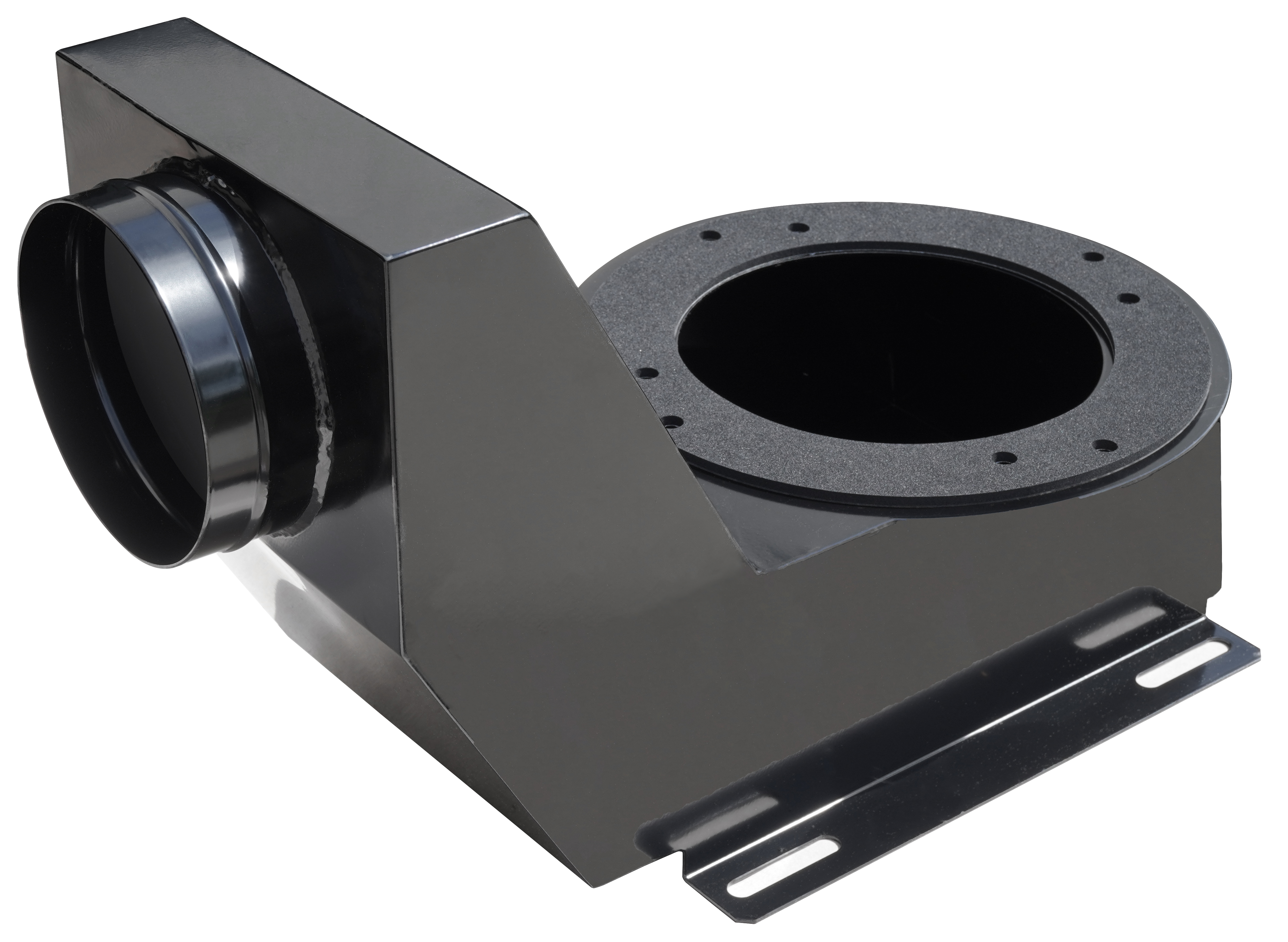

Single Part-Number Ordering and Universal Installation

- This advanced mounting system relocates the intake point to the side of the Filtermist unit for enhanced installation flexibility.

- Enables mounting virtually anywhere on top of the machine tool for optimal positioning of both the mist collector and intake location.

- Single part-number ordering – Royal Easy-Mount™ packages include everything needed for hassle-free installation:

- Royal Filtermist Unit

- Plenum with drain tube

- Standard After Filter

- Starter Box Kit

- Chip Deflector

- 6” Dia. Ducting (8ft.)

- 6” Ducting Clamps

- 6” Flange Adapter

- Coolant Return Hose (12 ft)

- All Required Hardware

- Extra Set of Drum Pads

Royal Easy-Mount™ Filtermist Mist Collector Packages

Description | Filtermist Model | Voltage | Intake Diameter | PART NUMBER | PRICE | |

|---|---|---|---|---|---|---|

FX-300 Easy-Mount™ Package (Low-Voltage) | FX-300 | 208/230 Volts | 6″ | $5,980.00 | ||

FX-300 Easy-Mount™ Package (High-Voltage) | FX-300 | 460 Volts | 6″ | $5,980.00 | ||

FX-575 Easy-Mount™ Package (High-Voltage) | FX-575 | 208/230 Volts | 6″ | $6,740.00 | ||

FX-575 Easy-Mount™ Package (Low-Voltage) | FX-575 | 460 Volts | 6″ | $6,740.00 | ||

FX-900 Easy-Mount™ Package (Low-Voltage) | FX-900 | 208/230 Volts | 6″ | $7,790.00 | ||

FX-900 Easy-Mount™ Package (High-Voltage) | FX-900 | 460 Volts | 6″ | $7,790.00 | ||

FX-1200 Easy-Mount™ Package (Low-Voltage) | FX-1200 | 208/230 Volts | 6″ | $8,210.00 | ||

FX-1200 Easy-Mount™ Package (High-Voltage) | FX-1200 | 460 Volts | 6″ | $8,210.00 |

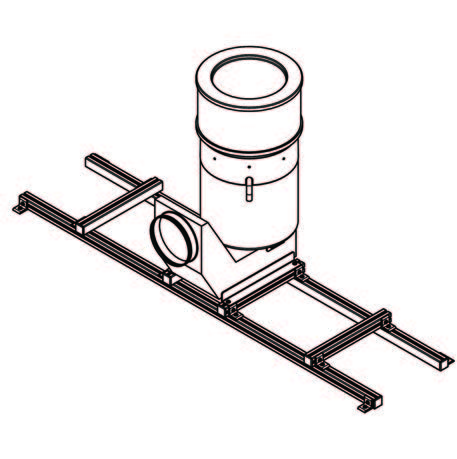

Provides Even Greater Filtermist Mounting Flexibility

- Heavy-duty rail kit can be used with any Royal Filtermist Easy-Mount™ Package to span openings/voids on top of the machine tool enclosure, making great use of “wasted space” on top of the machine.

- Rigid 40mm aluminum extrusions provide both strength and vibration-dampening capabilities. Rails are easily trimmable to the desired length.

- Rail Kit includes (3) six-foot lengths of 40mm extrusions – two for mounting the plenum and one to make stiffeners. All brackets, end caps, and hardware included for seamless integration.

Sizing Units

The Royal Filtermist is available in four sizes, based on throughput capacities: 300, 575, 900, and 1200 cfm. Royal Products maintains a database with specifications for many different machine tools, and we recommend you contact one of our applications engineers for your specific sizing requirements. For those who would like a general rule of thumb, we recommend using the following formula to obtain a rough idea of your requirements:

Filtermist Size = Internal Enclosure Volume x 5

For example, suppose you have a small CNC lathe with an internal work envelope measuring 5ft. wide x 3ft. deep x 4ft. high. Multiplying 5x3x4, we see that the machine has an enclosure volume of 60 cu. ft. Multiplying 60×5 we see that 300 cfm is required, so we’d choose the model FX-300.

Although this rule is very simple, it is handy for determining the general size requirements.

If you are not sure which unit to use, please contact your local Royal Filtermist Distributor or one of our applications engineers.

Grinding

Grinding applications can sometimes be more demanding than typical turning and milling applications because grinding produces fine dust particles that become entrained in the mist stream. Over time, this dust can accumulate on the drum pads, resulting in the need for more frequent maintenance. If regular maintenance is not performed and a significant volume of solid matter builds up in the drum, balance and vibration issues may arise.

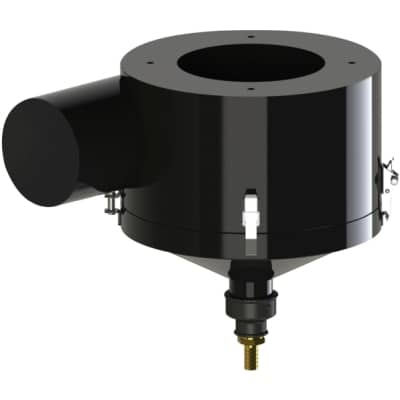

A simple way to overcome the problems associated with grinding dust is to fit the Filtermist with a cyclonic swarf separator. The separator mounts below the Filtermist unit and uses cyclonic action to separate out the solid matter, leaving the drum free to process the mist and preventing buildup on the pads. A port on the bottom of the unit facilitates drainage.

Royal Products recommends using a cyclonic swarf separator for all grinding applications.

Turning

CNC lathes are relatively easy applications to tackle because the machines are usually well enclosed and direct mounting is often possible. On any well enclosed machine, it is recommended that the Filtermist intake point be located as far from the machining action as possible so that the mist is drawn from an area of heavy concentration to an area of lighter concentration. On CNC lathes, therefore, the ideal intake location is on the right side of the machine, near the tailstock. On subspindle lathes where the right-hand wall moves along the z-axis, it might be necessary for the Filtermist to have a more central location.

Milling

For enclosed machining centers, the Filtermist intake position should be located in an upper corner of the enclosure. Installation on open-top machines is not as clear-cut. If enclosing the machine is not possible, a successful installation can often be accomplished by suspending the Filtermist unit above the machine and running ducting down into the enclosure. It may be necessary to adjust the intake location so that it is close enough to the spindle to collect the mist, yet far enough away to keep chips from being drawn in. A Y-junction may be used to draw mist from both sides of the spindle, and a chip deflector may also come in handy.

High-Pressure Coolant/Oil

More and more machine tools today are equipped with high-pressure coolant systems. Machines running either oil or coolant at high-pressure tend to create a greater volume of mist, with a smaller average particle size. For high-pressure applications, equipping your Filtermist unit with one (or both) of the performance accessories below will greatly help to optimize mist control within your shop.

High-Performance After Filter

This after filter has been specifically engineered for high-pressure coolant and oil applications. Laboratory and field performance tests have shown the service life to be as great as 10x that of a standard after filter.

Cyclonic Swarf Separator

While this accessory was originally designed to remove solid particulate entrained in the mist steam, it has also proven to be very effective as a pre-filter in high-pressure applications by removing much of the mist prior to the impaction process.

Risk-Free Performance Guarantee

Royal’s exclusive Risk-Free Performance Guarantee enables customers to try a Quick-Grip™ or Filtermist on the toughest jobs in their shop for 45-days, and if they are not 100% satisfied with the performance, Royal will take it back and arrange for a full refund.

The following conditions apply:

- The unit must be sized and installed appropriately for the particular machine and application. Contact us to verify the correct unit for your application.

- Credit will be issued for the unit, but may not be issued for ductwork, oil return hoses, etc., if they are not in resalable condition.

- The customer must contact Royal Products for a return goods number (RGA #). This number must appear on all paperwork and packaging of the unit being returned.

- The returned unit must be securely packaged and arrive at Royal Products in good condition.

If you have any questions about selecting the correct Royal Filtermist Unit for your application, please contact us.